Natural Gas Vehicle Challenge

Background

The Natural Gas Vehicle (NGV) Challenge began in 1991 when General Motors donated a GMC Sierra 2500 pickup truck to 24 engineering schools that submitted the best design proposals for the purpose of converting the vehicles to dedicated natural gas use. Natural gas was selected as the next fuel for the students to work with because the U.S. has an abundance of domestic natural gas resources and many natural gas companies were promoting its use in motor vehicles.

The schools converted the trucks to run on two forms of natural gas: two vehicles operated on liquefied natural gas (LNG) and 22 operated on compressed natural gas (CNG). The required modifications to the trucks were substantial and involved adding natural gas fuel tanks, adapting the fuel delivery system and engine control system, and modifying the exhaust system (i.e., catalytic converter) to minimize emissions. In addition, some schools used different compression ratios, engine displacements, and/or rear-end gear ratios to help increase fuel economy. The 1991 NGV Challenge was held in Oklahoma City, Oklahoma and the emissions testing was performed at the National Institute for Petroleum and Energy Research (NIPER) in Bartlesville, Oklahoma.

For the second year (1991-1992), 20 schools competed to refine their natural gas vehicle. After a year of refinement, a three-hour road rally was held at General Motors’ Proving Ground in Milford, Michigan. The best student vehicle got 17% better miles per gallon gasoline equivalent (mpgge) on the federal test procedure than the gasoline control vehicle. The emissions testing was performed at the U.S. Environmental Protection Agency in Ann Arbor, Michigan.

In the last year of NGV Challenge (1992-1993), five teams joined the competition for the first time. The final year was held in Austin, Texas for a 350-mile road rally. The emissions testing in 1993 was performed at EG&G Automotive Research in San Antonio, Texas and at the Natural Gas Vehicle Technology Center (NGV Tech Center) in Austin, Texas.

Natural Gas Vehicle Challenge

Natural Gas Vehicle Challenge

Natural Gas Vehicle Challenge

Natural Gas Vehicle Challenge

Natural Gas Vehicle Challenge

Natural Gas Vehicle Challenge

Inovations & Hightlights

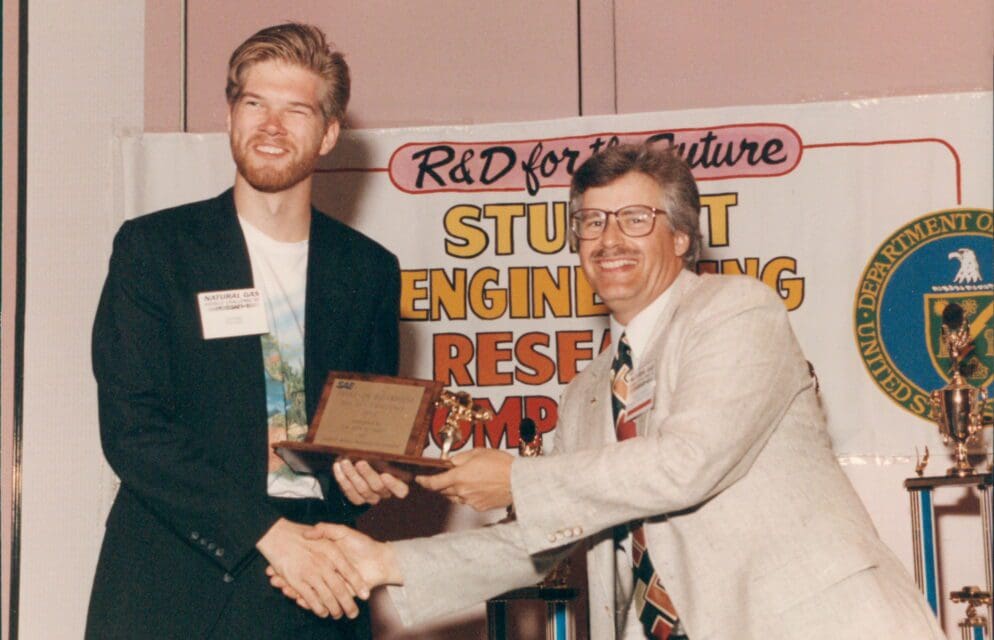

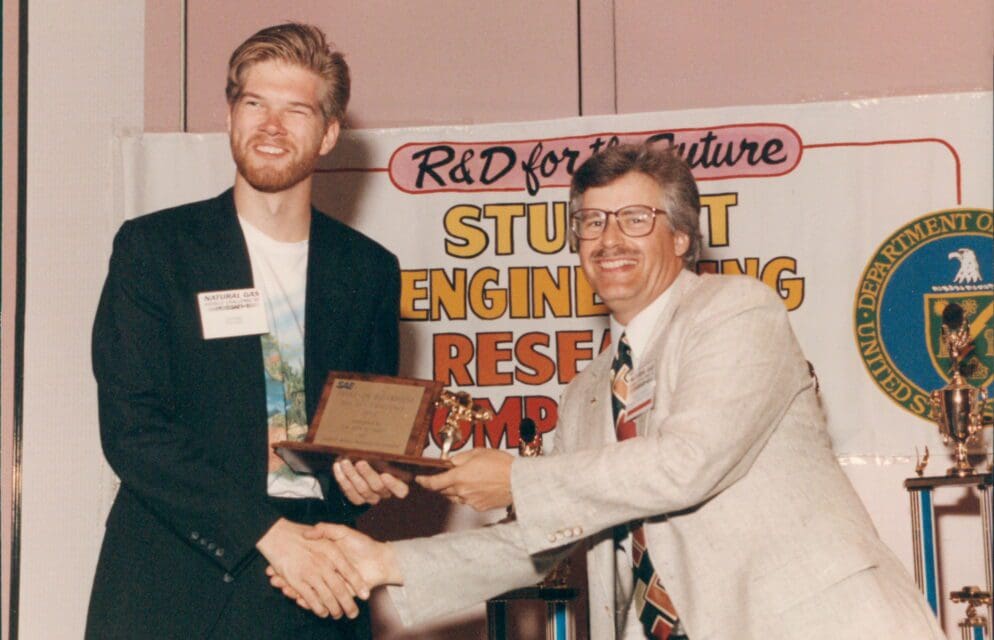

Over the three year competition, students were able to participate in an once-in-a-lifetime experience. During the competition, students impressed industry professionals with their vehicle designs and how they utilized natural gas.

One of the biggest innovations and highlights from NGV Challenge was that the average EPA combined fuel economy (from both the city and highway tests) went from 12.7 mpg in 1991 to 13.6 mpg in 1992 to 14.82 mpg in 1993. This was a steady and impressive progression. Below are some other highlights from the series.

- In the first year (1990-1991), only three teams earned points in the emissions event whereas in 1993, eleven teams met or exceeded the current federal emissions standards.

- Concordia and Northwestern measured the highest combined EPA fuel economy, with Northwestern getting 19.4 mpg as compared to the gasoline truck in 1991.

- In 1992, the top three fuel economies were Concordia at 20.8 mpg, Illinois Institute of Technology at 20.5 mpg and University of Nebraska at 19.5 mpg.

- Old Dominion University, in conjunction with Siemens Corporation, developed a gaseous fuel injector for its 1993 NGV Challenge vehicle

- In 1992, two LNG vehicles had the best ranges: University of Maryland with 423 miles and University of Alabama at 411 miles.

- Colorado State and University of Virginia measured the lowest engine-out emissions on the basis of their ranking in the categories of THC, NOx, and CO engine-out emissions in 1992.

- In 1992, the best CNG vehicles were Concordia University at 388 miles and New York Institute of Technology at 315 miles.

- Northwestern, General Motors Institute/Kettering, and the University of Toronto had the lowest emissions of all the universities over the FTP cycle in 1992.

- In 1993, best student vehicle got 14% better mpgge on than the federal test procedure than the gasoline control vehicle.

- Northwestern University developed an innovative gas-quality sensor that allows a closed-loop feedback engine control system to vary its parameters according to the gas content. This sensor was further developed by the Gas Research Institute.

- Old Dominion University and Siemens Automotive worked together to invent a multi-alternative-fuel injector that Chrysler put into production of their CNG vehicles

- Texas Tech university developed a CNG Conversion system that GM Mesa put into production

Universities Involved

California State University, Northridge

Location

Northridge, CalifoniaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Stewart Prince

Colorado State University

Location

Fort Collins, ColoradoVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Bryan Wilson

Concordia University

Location

St. Paul, MinnesotaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Tad Krepec

Ecole Polytechnique de Montreal

Location

Montreal, QuebecVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

Florida Institute of Technology

Location

Melbourne, FloridaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. John D. Thomas

GMI Engineering and Management Institute/Kettering

Location

Flint, MichiganVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Colin Jordan

Illinois Institute of Technology

Location

Chicago, IllinoisVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Francisco Ruiz

Instituto Technologico y de Estudios Superiores de Monterrey

Location

Monterrey, MexicoVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

New York Institute of Technology

Location

New York, New YorkVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

Northwestern University

Location

Evanston, IllinoisVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Richard Lueptow

Ohio State University

Location

Columbus, OhioVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Lawrence Kennedy

Old Dominion University

Location

Norfolk, VirginiaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Sidney Roberts

- Alan Wiggs and

- Taj Mohieldin

Texas A&M University

Location

College Station, TexasVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Tom Laik

Texas Tech University

Location

Lubbock, TexasVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Tim Maxwell

University of Alabama

Location

Tuscaloosa, AlabamaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

University of Alberta, Edmonton

Location

Edmonton, CanadaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. David Checkel

University of British Columbia

Location

Vancouver, British ColumbiaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

University of Maryland

Location

College Park, MarylandVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. David Holloway

University of Michigan, Dearborn

Location

Dearborn, MichiganVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Keshav Varde

University of Nebraska, Lincoln

Location

Lincoln, NebraskaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Joseph Borg

University of Oklahoma

Location

Norman, OklahomaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

University of Tennessee, Knoxville

Location

Knoxville, TennesseeVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Jeff Hodgson

University of Texas, Arlington

Location

Arlington, TexasVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Bob Woods

- Stephen Kugle

University of Texas, Austin

Location

Austin, TexasVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Ron Matthews

University of Texas, El Paso

Location

El Paso, TexasVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. Carroll Johnson

University of Toronto

Location

Toronto, OntarioVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

University of Virgina

Location

Charlottesville, VirginiaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

Washington University, St. Louis

Location

St. Louis, MissouriVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- None given

West Virginia University

Location

Morgantown, West VirginiaVehicle Design

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sit voluptates vero possimus enim non dicta aliquid veniam atque molestias, repellat cum unde vel sequi dolor at facilis corporis. Et, molestias labore quidem id impedit repellendus!Faculty Advisors

- Dr. James Smith

Winners & Awards

Each year, university teams compete in a variety of static and dynamic events that range from oral presentations to on-road vehicle testing to communications and business tactics. These static and dynamic events are judged by industry sponsors and professionals, both throughout the year and in-person at the year-end competition.

Below includes more detail about event awards and winners:

Year One 1990-1991

- 1st Place: University of Tennessee, Knoxville

- 2nd Place: Colorado State University

- 3rd Place: Concordia University

- 4th Place: Ecole Polytechnique de Montreal

- 5th Place: California State University, Northridge

Sponsors

Below are the list of sponsors who helped make Natural Gas Vehicle Challenge possible:

Natural Gas Vehicle Challenge Media Coverage

Select a tab above to view content

- Young minds ‘fuel’ CSU program

- Class designs top gas vehicle – naturally

- Natural Gas Vehicle Challenge Research in Motion – June 7, 1991

- Tennessee Students Win Natural Gas Challenge – June 13, 1991

- Class Designs Top Gas Vehicle-naturally – June 20, 1992

- Students Make ‘Final Four’ – July 11, 1993

- OU Looks at Liquefied Gas Technology – April 2, 1994