Propane Vehicle Challenge

Background

The Propane Vehicle Challenge (PVC), held between 1995 and 1997, focused on converting 1996 Chrysler Minivans into dedicated propane vehicles, while maintaining the performance that consumers expected from gasoline vehicles.

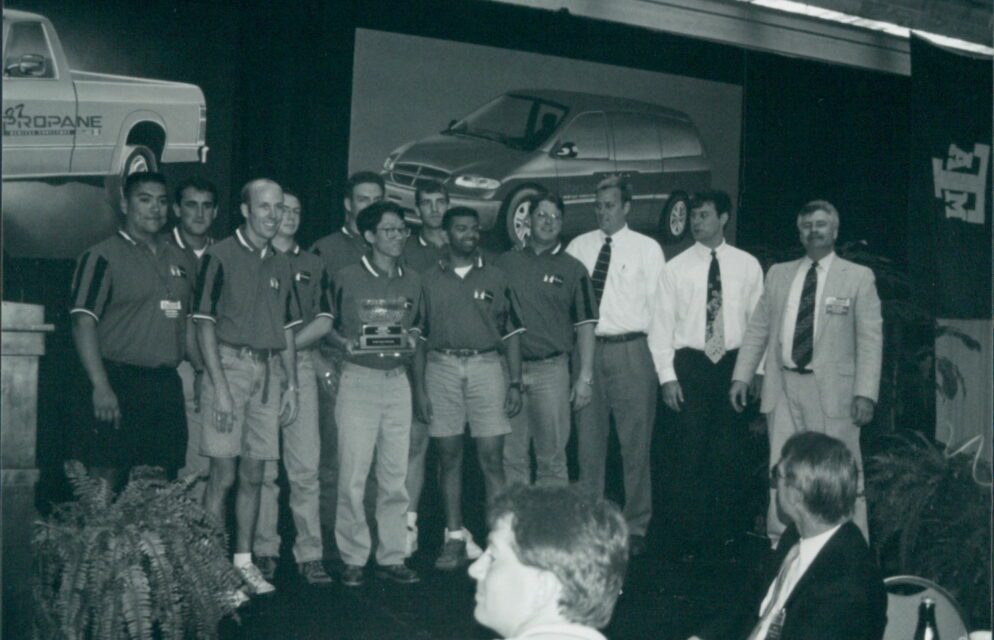

Featuring 12 universities, these teams competed in a series of dynamic and static events at the Chrysler Canada and University of Windsor facilities in Windsor, Ontario before embarking on an over-the-road range event from Windsor to Toronto. The winning entries met the range goal of at least 250 miles with no problem, and the University of Texas at El Paso entry achieved an incredible estimated range of 716 miles upon refueling.

During the 1996-1997 Propane Vehicle Challenge, 17 different universities from North America competed. Veteran teams were able to refine their Chrysler Minivans, while new teams had the chance to convert Dodge Dakota pickup trucks.

Vehicles underwent state-of-the-art emissions testing and presented their design strategies and vehicles to a team of industry judges for evaluation at the Southwest Research Institute in San Antonio, Texas. Teams drove to the Texas World Speedway in College Station and competed in acceleration, handling, and fuel economy events. The teams completed the remaining events in Austin, Texas. For the first time, an award was given for the best component to the University of Texas at El Paso for the development of fuel-distribution spiders. This was a novel fuel-rail design that ensured equal distribution (temperature and pressure) of liquid-phase LPG to each fuel injector.

The Propane Vehicle Challenge

The Propane Vehicle Challenge

The Propane Vehicle Challenge

The Propane Vehicle Challenge

The Propane Vehicle Challenge

The Propane Vehicle Challenge

The Propane Vehicle Challenge

Inovations & Hightlights

PVC goals were to develop advanced propane vehicle technology, achieve ultra-low emission vehicle (ULEV) standards, attain a minimum range of 250 miles, and demonstrate performance equal to or better than that of an equivalent gasoline-fueled vehicle.

- For the first time, an award was given for the best component to the University of Texas at El Paso for the development of fuel-distribution spiders. This was a novel fuel-rail design that ensured equal distribution (temperature and pressure) of liquid-phase LPG to each fuel injector.

- One of the evaluation tests included a road rally from Windsor to Toronto, about 250 miles, without refueling.

- University of Windsor achieved ULEV standards in 1996.

- Texas Tech University beat the acceleration of the standard gasoline-powered minivan in 1996 by .05 seconds, with their acceleration time taking 11.52 seconds.

- Illinois Institute of Technology achieved 20 MPG, exceeding the fuel economy of a standard minivan.

- GMI Engineering & Management Institute achieved LEV standards in 1996.

- University of Texas at El Paso achieved an estimated range of 716 miles upon refueling.

- The University of Alberta, Edmonton achieved the best fuel economy when they achieved 22.8 MPG (31.2 miles per gallon gasoline equivalent (mpgge).

Universities Involved

Ecole de Technologie Superieure

Location

Montreal, Quebec, CanadaFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

Texas A&M University

Location

College Station, TexasFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

Texas Tech University

Location

Lubbock, TexasFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

University of Oklahoma

Location

Norman, OklahomaFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

University of Puerto Rico, Mayaguez

Location

Mayaguez, Puerto RicoFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

University of Tennessee, Knoxville

Location

Knoxville, TennesseeFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

Villanova University

Location

Philadelphia, PennsylvaniaFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

Virginia Tech

Location

Blacksburg, VirginiaFaculty Advisors

- First Name, Last Name

- First Name, Last Name

- First Name, Last Name

Winners & Awards

Each year, university teams compete in a variety of static and dynamic events that range from oral presentations to on-road vehicle testing to communications and business tactics. These static and dynamic events are judged by industry sponsors and professionals, both throughout the year and in-person at the year-end competition.

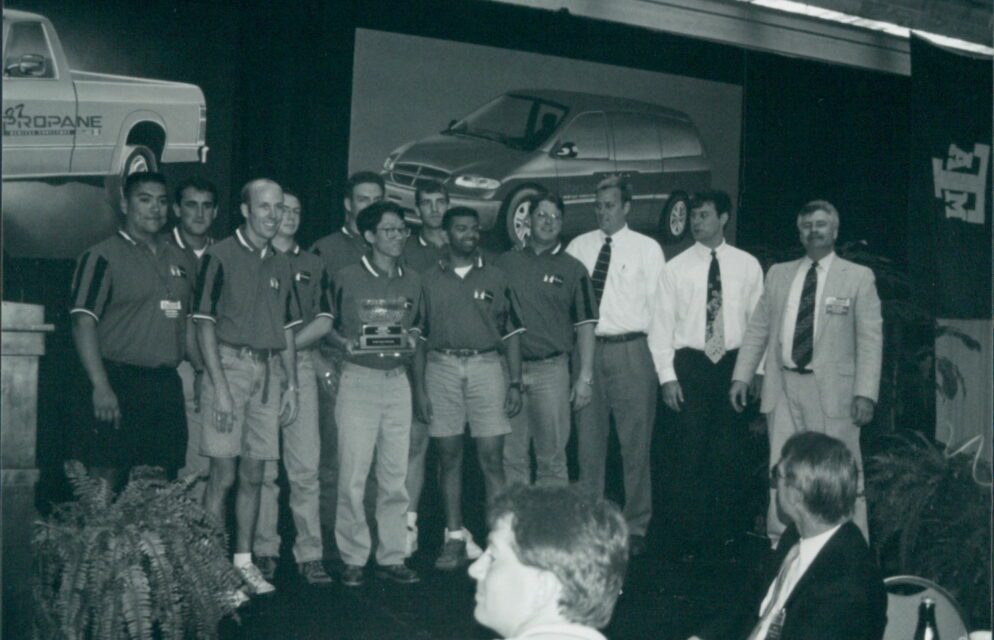

Year One 1995-1996

- 1st Place – Texas A&M University

- 2nd Place – GMI Engineering & Management Institute/Kettering University

- 3rd Place – University of Texas at El Paso

- 4th Place – University of Alberta, Edmonton

- 5th Place (tie) – Texas Tech University and Western Washington University

- Best Propane Conversion – University of Texas at Austin

- Lowest Emissions – Texas A&M University

- Best Fuel Economy – Illinois Institute of Technology

- Best Teamwork Award – University of Texas at Austin

- Simon Vega Sportsmanship Award – University of Alberta

Year Two 1996-1997

Chrysler Minivan

- 1st Place – GMI Engineering & Management Institute/Kettering University

- 2nd Place – Texas Tech University

- 3rd Place – University of Texas at El Paso

- 4th Place – University of Alberta, Edmonton

- 5th Place – Western Washington University

- Best Oral Presentation – Texas Tech

- Best Propane Conversion – University of Alberta, Edmonton

- Best Engine Out Emissions – University of Alberta, Edmonton

- Lowest Emissions – Texas Tech

- Most Improved Team – Texas Tech

Dodge Dakota

- 1st Place – University of Waterloo

- 2nd Place – Texas A&M University

- 3rd Place – University of Tennessee, Knoxville

- 4th Place – University of Windsor

- 5th Place – Virginia Tech

- Best Oral Presentation – University of California, Riverside

- Best Propane Conversion – Texas A&M University

- Best Engine Out Emissions – University of Waterloo

- Lowest Emissions – University of Waterloo

- Most Improved Team – University of Waterloo

- Best Fuel Economy – University of Tennessee, Knoxville

Other Awards

- Simon Vega Sportsmanship Award – University of Alberta, Edmonton

- Most Innovative Component – University of Texas at El Paso

- Best Teamwork – University of Kansas

- Best Skit – University of Windsor

Sponsors

Below are the list of sponsors who helped make Propane Vehicle Challenge possible:

Propane Vehicle Challenge Media Coverage

Select a tab above to view content

- OU Team Faces Propane Vehicle Design Challenge – Feb. 23, 1996

- UT engineers students reclaim victory in Propane Vehicle Challenge – June 13, 1997

- Propane Vehicle Challenge by Southwest Research Institute – Fall 1997

- Propane Vehicle Challenge via AFDC – January 1996

- Lincoln-Way grads get in gear via Herald-News

- Propane Projects Meet the Challenge – May 18, 1997

- Engineering students tinker with ‘car of the future’ via UIC News

- The GMI Fuel Injected Propane Conversion Kit

- Emissions Results for Dedicated Propane Chrysler Minivans: The 1996 Propane Vehicle Challenge

- 1997 UTEP LPP-FI Propane Challenge Vehicle

- Development of an Advanced, Low-Emitting Propane-Fueled Vehicle, November 1997

- Alternative Fuel Vehicles: Should the Federal Government Bridge the Economic Gap?, 1997