By Em Jankauski

The future is most certainly bright. That’s the takeaway for Battery Workforce Challenge students, faculty, sponsors and organizers who recently wrapped up the year two winter workshop held Feb. 27 through March in Greenville, S.C.

“These workshops are truly such a unique opportunity for our BattChallengers,” said Ajay Gnanasekaran, BattChallenge director. “They give students unique access to industry leaders, allowing them to seek advice on their designs, ask technical questions or seek career advice.”

Day one: Networking and learning

Ready indeed. Students hit the ground running day one of the workshop, held at the Hilton Greenville, as they listened to plenary speakers Gnanasekaran, Micky Bly, Stellantis’ senior vice president and head of global propulsion systems; and Alycia Gilde, U.S. Department of Energy’s senior advisor for transportation and partnerships.

“I really hope you appreciate what you have around you,” said Bly, elaborating on the multitude of reasons why students should be grateful for this three-year competition — from their teammates, Stellantis mentors, the premiere industry sponsors and “unbelievable” access to the U.S. government through the Department of Energy providing them with unique access. “You’ve got multiple layers of opportunity.”

He reminded students that while, yes, their competition vehicle is a RAM ProMaster EV, a delivery vehicle important to consumers like Amazon, FedEx and the U.S. Postal Service, it’s also the same technology going into the automaker’s trendy models like the Dodge Daytona.

“You may think you’re working on a battery pack that goes into a shipping van, but the same technology you’re working on is going into this car,” Bly said. “And this car is really about what excites my engineers; it excites me every day.”

Gilde also urged the crew to draw inspiration from their time in the competition. She asked them to consider how their time spent in the BattChallenge is laying the foundation for their future career in the automotive industry.

“I would not be where I am today if I didn’t seize every opportunity that I could to get that real-world experience,” said Gilde, recalling mentors and friends she met along the way that she remains in contact with to this day. “I say all of this because you never know where your path is going to lead you.”

Her advice for BattChallengers?

“No matter which way your career brings you, the future is there for you to be creative,” Gilde said. “Find ways to take the path less followed. Look at ways in which you can challenge yourself.”

Later, students got the chance to network with competition sponsors during the sponsor social. Organizers put a little spin on this event, holding a couple of friendly competitions between the teams and individual BattChallengers for the chance to win an hour-long phone call with Eaton and Stellantis execs, respectively.

Sponsors in attendance during the event included Stellantis, BIC, Eaton, AVL, Analog Devices, Gamma Technologies, MathWorks, Vibration Research and Volta Foundation.

The sponsor social was a particularly meaningful part for Deirdra von Frame, Colorado School of Mines & Arapahoe Community College BattChallenge team’s vocational lead, who was able to chat with Gilde about her plenary session remarks and shared how she personally related to it

“I’m so grateful I was able to make a close connection with her,” von Frame said. “That was 100 percent one of the biggest things that resonated with me.”

Students also received several engineering, communications and project management-related trainings by competition organizers and sponsors.

For Harpreet Mann, communications lead for the University of Michigan-Dearborn & Henry Ford College’s BattChallenge team, that one-on-one time with sponsors was critical.

“One major takeaway was the power of feedback — not just receiving feedback but also implementing it in meaningful ways,” Mann said. “It’s not just about designing to meet competition requirements, but (it’s) about pushing for continuous improvement.”

Day two: Industry-level feedback

Days two and three took place at Greenville Technical College’s Center for Manufacturing Innovation. Day two kicked off with a battery panel discussion, titled Watt’s Next? Energizing the Battery Workforce. Featured panelists include Bly, Mark Champine, Stellantis’ senior vice president and head of North America engineering technical centers; Gilde, Ryan Melsert, ABTC’s CEO and CTO; and Kristen Wahl, Argonne National Laboratory’s Sustainable Transportation Education and Partnerships director.

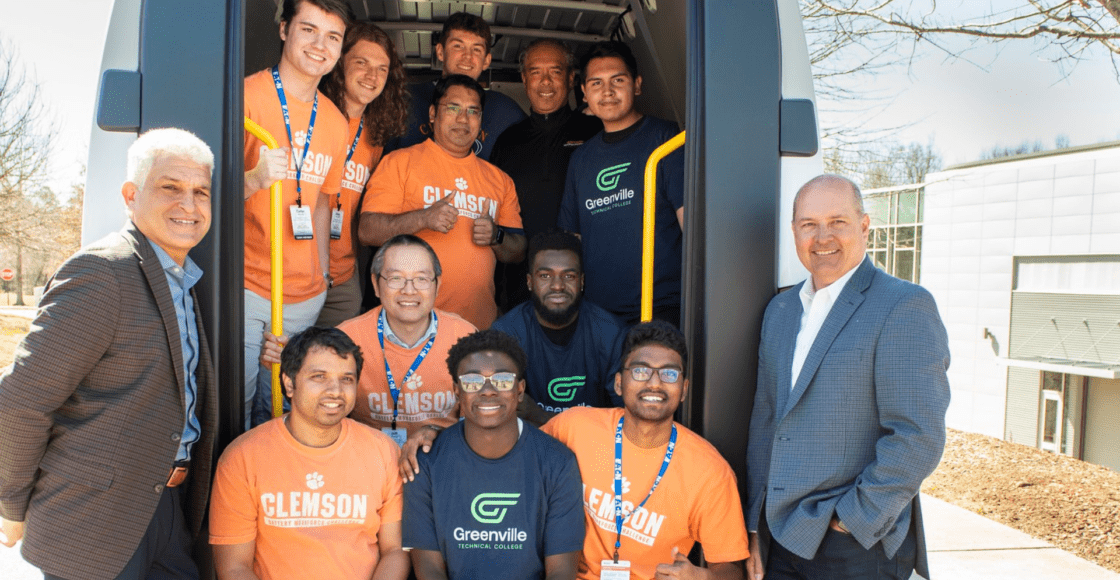

A van delivery media event immediately followed the panel. Here Stellantis’ Bly and Champine delivered the Clemson University & Greenville Technical College team’s RAM ProMaster EV. Gnanasekaran, Jiangfeng (Jeff) Zhang, the team’s lead faculty; Maurice Grady, vocational lead faculty and student representatives Saroj Paudel and Terell Gamble chatted with attending media.

From here, each team conducted its thermal, software and module design reviews, providing each crew with industry-level feedback on its designs from the competition’s attending sponsors.

“The most impactful interactions with the sponsors for me has always been their encouragement after technical reviews,” said Parker Hewett, battery pack hardware lead for the Colorado School of Mines & Arapahoe Community College BattChallenge team. “No matter how many hard questions they ask you, they always come out after and let you know that they are impressed.”

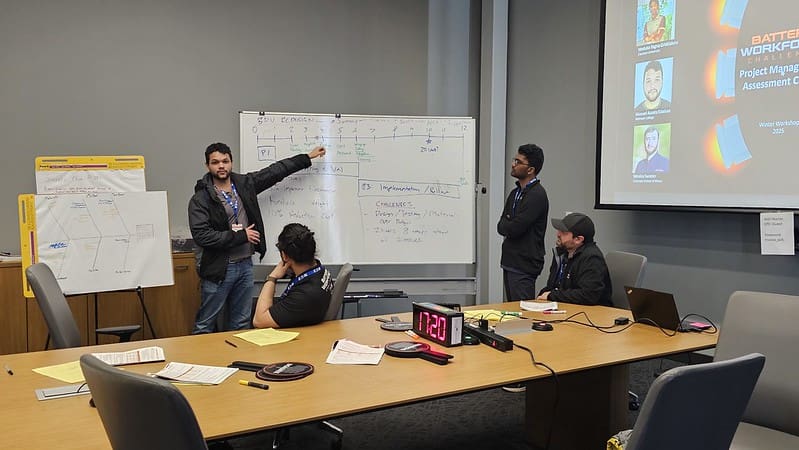

Project managers and vocational deputies from each of the 12 teams also participated in the Project Management Assessment Center, completing a statement of work for their welding strategy and presenting it to a panel of judges from Analog Devices, Argonne National Laboratory, Eaton and Stellantis.

For Cameron Zimmer, vocational BattScholar for the Colorado School of Mines & Arapahoe Community College’s BattChallenge team, the PMAC was his favorite part of the workshop.

“It was actually a really cool and unique experience,” Zimmer said. “We had to work with the members from other teams to try and solve this problem.”

Teammate Wesley Swieter, project manager for the Colorado School of Mines & Arapahoe Community College’s BattChallenge team, couldn’t agree more, sharing that the industrial strategy presentation portion of the PMAC was his favorite part of the workshop.

“It was a privilege and an honor to sit with industry leaders and get their feedback,” Swieter said. “I’m refining the project management skills I’ve learned in my master’s program through simulated real-world experience.”

Later that evening, teams were treated to a barbecue dinner local improv group Alchemy Improv performed a private show for the BattChallengers.

Day three: Taking initiative

On the last day of the workshop, BattChallenger teams continued their thermal, software and module design reviews as well as participated in the PMAC. This time, project managers and vocational deputies were given a case study to review, independently, for 30 minutes, and then as a group, they worked collaboratively to formulate a project initiative and presented their efforts to the same panel of judges mentioned previously.

An additional workshop festivity included the BattChallengers highlighting their teams’ experiences in real-time on social media. Each day, organizers gave students a prompt to share about on their respective LinkedIn pages. Teams that posted each prompt could then submit their engagement rate post-workshop for a chance to win an extra seat to the year two competition.

“These workshops are both great learning experiences that help us gain a better technical understanding of the software/systems that we are using,” said Ritvik Durgempudi, Colorado School of Mines & Arapahoe Community College BattChallenge team’s battery pack software lead. “(These are) great places to interact and connect with other teams and sponsors to forge important connections.”

Jake Tipsword, Colorado School of Mines & Arapahoe Community College BattChallenge team’s vocational advisor, couldn’t agree more sharing that opportunities like these are critical for his automotive students.

“The automotive industry is evolving at an unprecedented pace, and the skills being developed in this challenge aren’t just about this competition — they are about future-proofing careers,” Tipsword said. “The ability to work collaboratively, apply first principles problem solving and execute on OEM-level (original equipment manufacturer) standards is what will set these students apart as they move into the workforce.”

***

That concludes the BattChallenge’s Year Two Winter Workshop activities. Follow us on LinkedIn to see all the action from last week’s workshop.

The year two competition will be held in the Indianapolis area from May 4-9.