Written by: Kyle Wyndham-West

In the ever-evolving landscape of automotive engineering, where technological innovation stands as the cornerstone of progress, the software provided by our sponsors stand as a crucial tool to the evolution of our vehicle and electric vehicles. Our team’s endeavors are underpinned by the utilization of MathWorks software, utilized across multiple sub teams, a suite of advanced tools that has proven instrumental in propelling the ground-breaking projects that we take on every day. This discourse delves into the superlative attributes of MathWorks software and its indispensable role within the McMaster EcoCAR team’s engineering pursuits.

The Efficacy of Simulink:

At the nucleus of the McMaster EcoCAR team’s accomplishments lies Simulink, a sophisticated simulation tool from MathWorks. Simulink furnishes a multidomain simulation environment, affording the team the capability to model, simulate, and analyze intricate systems with unparalleled precision. In the context of conceiving a direction for our team throughout the competition, Simulink has become an indispensable asset, facilitating the team’s capacity to iteratively refine and optimize our designs with remarkable efficiency.

Model-Based Design Driving Automotive Innovation:

Model-Based Design stands as a methodology synonymous with the pioneering practices of premier automotive teams globally. The McMaster EcoCAR team has wholeheartedly embraced this methodology, thanks to MathWorks’ comprehensive suite of tools. Model-Based Design not only expedites the development process but also fortifies collaboration amongst team members, fostering seamless integration of diverse components into the final vehicle design.

MATLAB: A Pervasive Toolkit for Engineering Excellence:

The McMaster EcoCAR team employs MATLAB, another flagship product from MathWorks, to undertake a myriad of engineering tasks. From diligent data analysis to the development of intricate algorithms, MATLAB’s versatility empowers the team to address a spectrum of challenges inherent in the development of our eco-friendly vehicle. The seamless integration of MATLAB with Simulink yields a cohesive workflow, effectively streamlining the entire design and testing process.

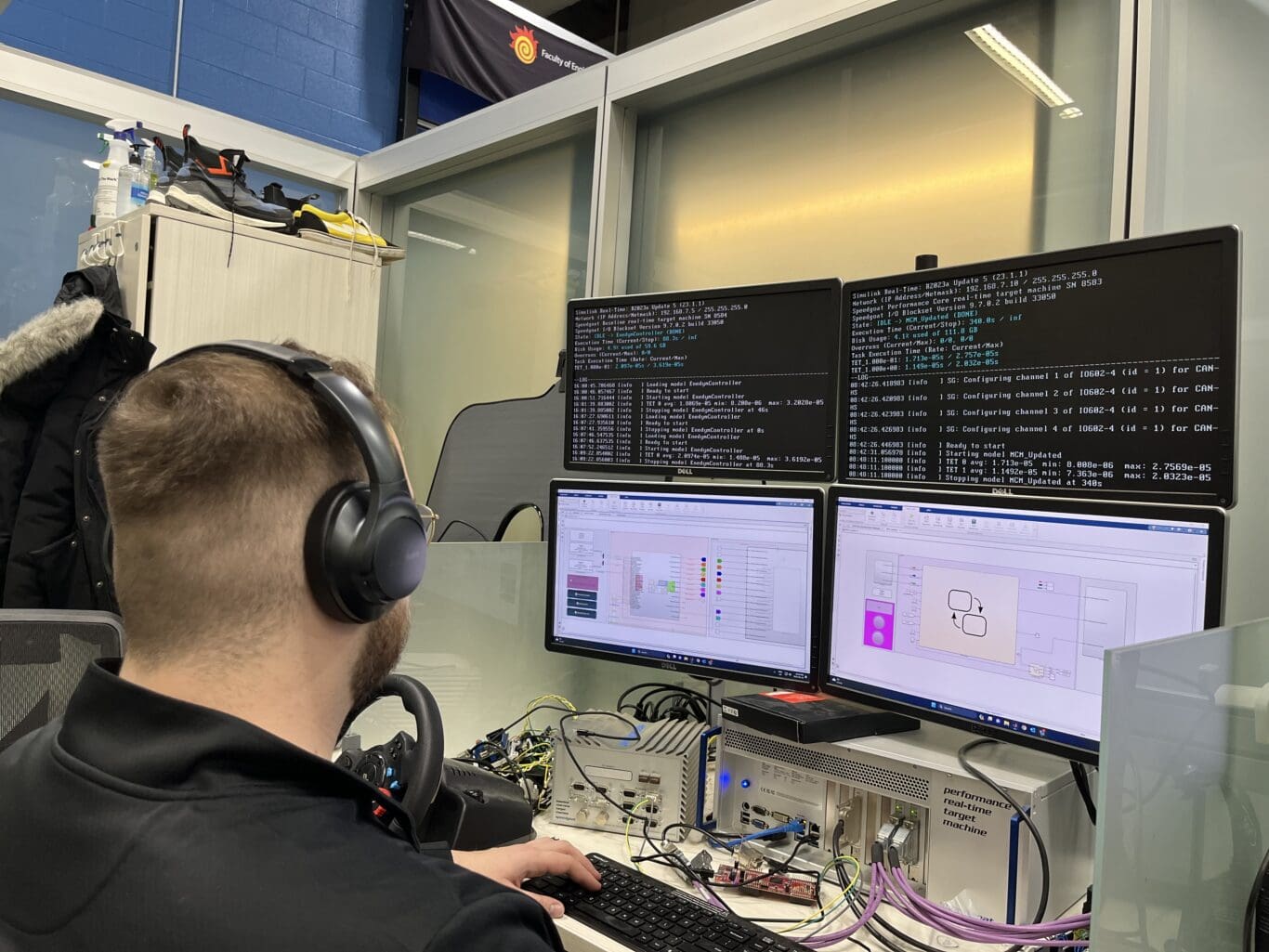

Real-Time Testing through Hardware-in-the-Loop (HIL) Simulation:

A hallmark of the McMaster EcoCAR team’s methodology is the implementation of Hardware-in-the-Loop (HIL) simulation. MathWorks’ HIL capabilities facilitate real-time validation of designs, replicating authentic driving conditions without necessitating a physical prototype. This not only expedites the testing phase but also ensures that the final product aligns with the most stringent standards of performance and efficiency.

Optimization and Iteration: Pillars of Sustained Success:

In the realm of automotive engineering, continual refinement stands as the modus operandi. MathWorks software equips the McMaster EcoCAR team with robust optimization tools, facilitating the fine-tuning of our designs through iterative processes. Whether enhancing fuel efficiency, curbing emissions, or elevating overall vehicle performance, MathWorks software provides the tools essential for achieving our high standards and increased levels of optimization.

A testimony from one of our most tenured members, Lucas Rajotte the Propulsions, Controls, and Modelling Lead, says it all about how important this relationship is: “I learned how to use MATLAB when I joined the team. From day one I found MATLAB, Simulink, and Stateflow to be the most useful development platform for almost anything. EcoCAR, capstone, class projects etc., not only do they have the right tools and block-sets, but they also have unmatched documentation on nearly everything they make. That paired with the amazing support from Sam as well as our mentor Joel has made learning and growing with MATLAB 10x easier. MATLAB is easily my favourite piece of software in existence. Its also a big contributor to where I am in my career today.”

The collaboration between the McMaster EcoCAR team and MathWorks epitomizes the influence of state-of-the-art engineering tools in the pursuit of sustainable automotive solutions. As the team persistently pushes the boundaries of innovation, MathWorks remains a crucial puzzle piece in the greater picture, providing the tools and technologies essential for conceptualizing ambitious engineering endeavors. The synergy between McMaster EcoCAR and MathWorks exemplifies how technology can drive innovation within the automotive industry on all levels, shaping a future where eco-friendly vehicles stand as the norm rather than the exception.

As we enter Year 3 of the competition, stay tuned to our social media pages to see the how we have implemented the technologies in real life testing.