Written by: Angel Tran, Communications Manager

As Year 3 of the EcoCAR EV Challenge has come to an end, the UC Riverside team is proud to celebrate a progressive year marked by technical breakthroughs, refined integration, and close-knit sponsor collaboration. From spinning wheels for the first time to executing robust vehicle testing, our team has reached milestones that lay the foundation for an even stronger Year 4.

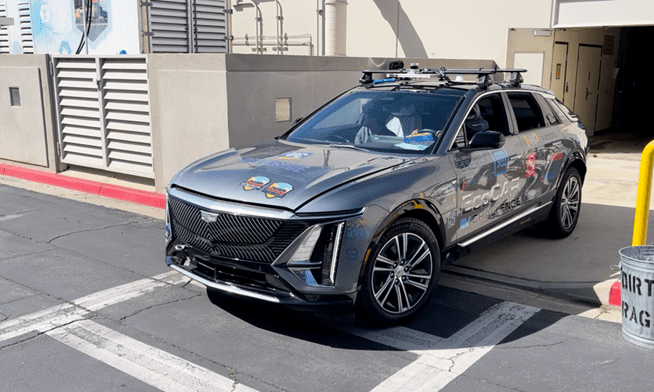

One of our most notable achievements from this year was when the team reached a brand-new vehicle integration milestone. Through a dedicated effort by our System Design and Integration (SDI) subteam, we successfully commanded torque for the first time — allowing the LYRIQ to spin its wheels and begin limited drive testing. This moment was a major turning point in validating our control systems and marked the culmination of months of collaboration across subteams.

During the Year 3 Competition, our team successfully passed Vehicle Technical Inspections and the On Road Safety Evaluation in Yuma, AZ. Our team was nominated and received the Ron Stence Spirit of the Challenge Award, which celebrates teams who exemplify remarkable resilience in the face of adversity. In addition, PCM Lead, Nilesh Balusu, received the 1st Place Excellence in Leadership Award for his high level of technical competence and initiative to go beyond his role to support other subteams, mentor new members, and contribute to the broader EcoCAR community.

The road to these accomplishments was paved with the support of generous sponsors who provided not just hardware and software, but valuable mentorship and troubleshooting guidance. Here are a few key comments our team leads had to say.

“American Axle and Manufacturing (AAM), played a pivotal role throughout this year,” said Will Synder, SDI Lead. “Their team was always extremely eager to assist our team with the various ongoing issues with our EDU. They offered resources that allowed us to confirm the proper installation and provided key support for the Powertrain and Controls (PCM) team’s torque path calibration.”

The PCM subteam made huge strides thanks to MathWorks, Speedgoat, and Vector. MathWorks’ Simulink enabled rapid prototyping of our control algorithms in-vehicle. The Speedgoat Baseline controller powers our LYRIQ, while the Performance unit serves as our HIL (Hardware-In-the-Loop) bench. Vector’s suite — including CANalyzer, CANoe, CANdb++, and CANape — along with hardware like the GL2400 and VN1630A, has been instrumental in real-time logging, calibration, and system validation.

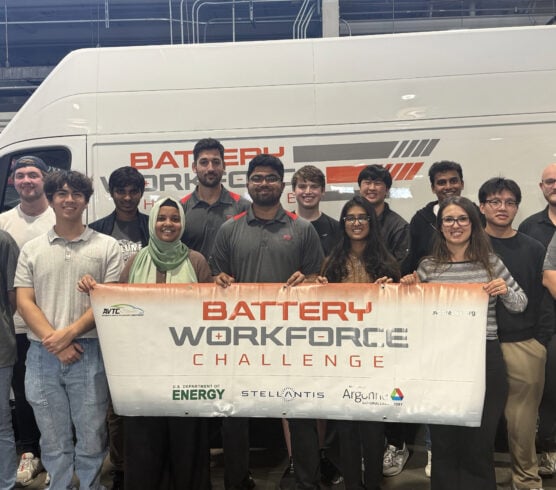

The UC Riverside EcoCAR team also recognizes Argonne National Lab (ANL), General Motors (GM), and dSPACE for their consistent mentorship and speedy support in resolving questions and concerns during the development phases.

This year’s goal was primarily focused on unlocking functionality — now Year 4 will be about refinement and precision. Our focus will shift toward optimization, rigorous validation, and competition readiness. The team is excited to carry this momentum forward, and we’re incredibly grateful for the sponsors and mentors who helped get us to this point.