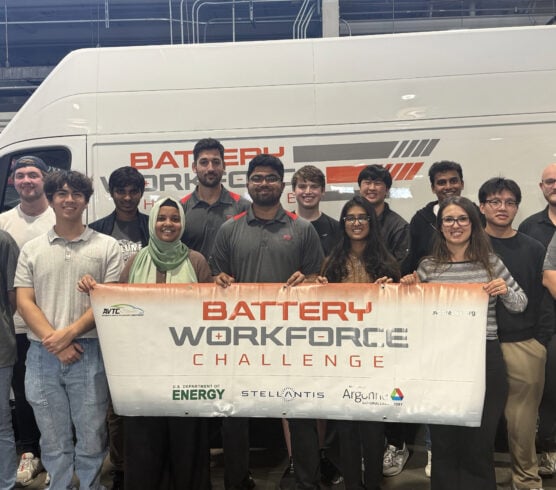

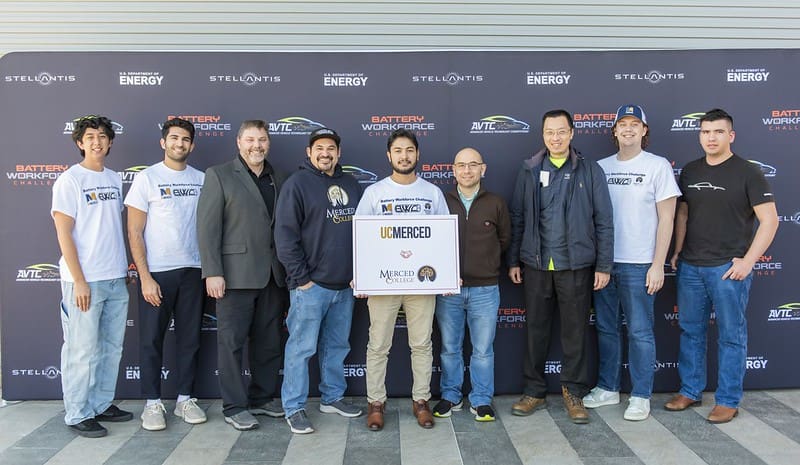

By Nicolas Perez Yen, Ali Dilawer and Anson Yee / University of California, Merced & Merced College

Cold plates play a critical role in facilitating the temperature of batteries over long periods of time and offer many benefits including a boost in overall lifespan, consistent performance and peak efficiency while in use. The University of California, Merced & Merced College BattChallenge team wants to express its gratitude to Dana for offering us the opportunity to gain an insight into the manufacturing aspect of cold plates and continuous response to our efforts throughout this integration phase of the challenge.

Dana has sponsored some of our other current utilities for the competition, headlined by the M450 component, an embedded controller that acts as the main processor for battery management, providing supplemental support towards monitoring overall performance from the battery.

With our initial connection to Ben Kenney’s, Dana’s engineering manager, presentation last summer ranging on various topics, including the design and manufacturing process to the criteria for channel designs to an insight into the brazing process for these cooling plates.

It was an incredible look into the industry and thought process behind the overall design process behind cold plates meant for battery cooling.

Ranging from learning about the normal design methodology of cold plates such that the number of ribs support minimal yielding and battery cooling, to seeing the slight differences in machine and stamped manufacturing, to understanding the importance in channel design and unsupported bracket measurements, our connection to Dana has been eye-opening to the various possibilities and opportunities within the manufacturing field, building up our fascination and interests centered around product quality and design.

Ever since this presentation, we’ve had weekly meetings with Dana mentors while designing our cold plates, which are an invaluable experience. Dana’s offered its input in certain aspects of engineering to look out for when designing, and it’s also provided a look into how we may be able to improve our designs.

With our thermal team having little experience with design and cold plates at the start, having this strong connection with Dana and its input towards our design has been extremely beneficial with our overall learning and dive into the design industry. This connection to a company as great as Dana, which has powered innovation for decades, allows students to place a focus on their studies and can lead to many great opportunities in the growing field of manufacturing.

Ever since this presentation, we’ve had weekly meetings with Dana mentors while designing our cold plates, which are an invaluable experience. Dana’s offered its input in certain aspects of engineering to look out for when designing, and it’s also provided a look into how we may be able to improve our designs.

With our thermal team having little experience with design and cold plates at the start, having this strong connection with Dana and its input towards our design has been extremely beneficial with our overall learning and dive into the design industry. This connection to a company as great as Dana, which has powered innovation for decades, allows students to place a focus on their studies and can lead to many great opportunities in the growing field of manufacturing.

Some of our students currently working under the thermal team and directly with Dana can build up to internship and job opportunities, allowing students to use its representatives’ expertise in which they have developed throughout the competition and incorporate them into their careers.

With our current developments, we would like to thank Dana once again for its continuous contributions to our team and especially the competition through its support and guidance under this developing industry.

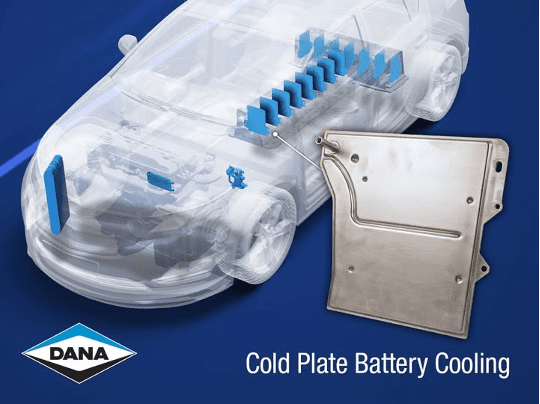

Cold Plate Battery Cooling is an essential component for the battery within an electric vehicle, and the corresponding image shows an inside look as to how cold plates are necessary for various parts within the car, ranging from the power electronic to the motor and especially the battery. Battery cooling advances thermal efficiency, and with the support of Dana, will maintain a focus on regulating temperature levels for the vehicle and efficient management in component systems.

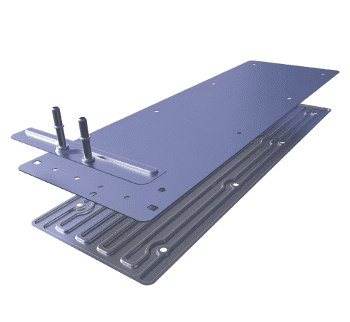

Dana has led us towards the overall design and advancement of our very own cooling system cold plate to be used throughout the duration of the challenge. This image from Dana is a representation of a workspace that will aim to construct our designed cold plate piece to be integrated into the Ram ProMaster electric vehicle.

This is a representation of a cooling plate which we aim to utilize in our final design of our emergency electric vehicle. Dana has offered their insight and given us invaluable support in working towards constructing a cold plate design, along with their endorsement in the manufacturing process of the plates themselves.