Written by: Chloe Madison, MSU Communications Manager

Welcome to MSU EcoCAR’s crib! We are so excited to showcase our garage and all the equipment that we are so fortunate to have. In this video we have our System Design and Integration (SDI) Lead, Nathan Reynolds, giving the tour of the garage. With the significant amount of time Nathan has spent in the garage working on the past project with the Chevy Blazer, he knows the ins and outs of this space. In addition, Nathan shows our office where all our leads come to work every day.

In our garage, we take safety very seriously and that is why the first item Nathan hands me is a pair of safety glasses. In the garage, we have yellow lines enclosing each work area, and it is a strict rule that no one can cross those yellow lines without safety glasses. You can see last year’s competition vehicle, the Chevy Blazer, is on the lift. The lift is what we use to access the underside of the car to make integration easier. Next, we pan to the pack out shelf which is where we hold all our traveling supplies. The top of the shelf holds special communications equipment and event items. The consumables cabinet next to the shelf holds all the connectors, fasteners, and tapes we may need. Next to the consumables is the sanitation cabinet which holds all cleaning equipment. In addition, we have a work bench at the front of the bay, and under it are the toolboxes. This is where we store any tools the team needs to use. We then move to the lift controls and yellow spill kit in the corner. Beside those is the electrical toolbox that holds all the electrical components needed for the vehicle. Lastly, is the “Wall of Education” where components have been stripped from previous vehicles and labeled. It provides a place to show students how components fit together and work to educate them on automobile functionality.

After viewing the garage, Nathan shows our team leads’ office where all the leads come to work every day. We each have our own desk and computer where we can collaborate and work together on different tasks and deliverables. As you can see, we have a 3D printer which turns a CAD model or a 3D model into a three-dimensional object. Beside the 3D printer is our snack and coffee area which we utilize on long nights. This is an inclusive space, so we encourage and appreciate when sub-team members come into the office to work with us.

One space we were not able to show in the video is our Chassis Dynamometer Control room (Dyno). In this photo is our SDI Lead Nathan Reynolds and our Chief Engineer/ Technical Specialist Jagdeo Singh working hard in the Dyno control room. This space is used to run the car without it having to be on the road. In addition, we use the dynamometer to run drive cycles and collect data on energy consumption. We then use this data when integrating components into the vehicle.

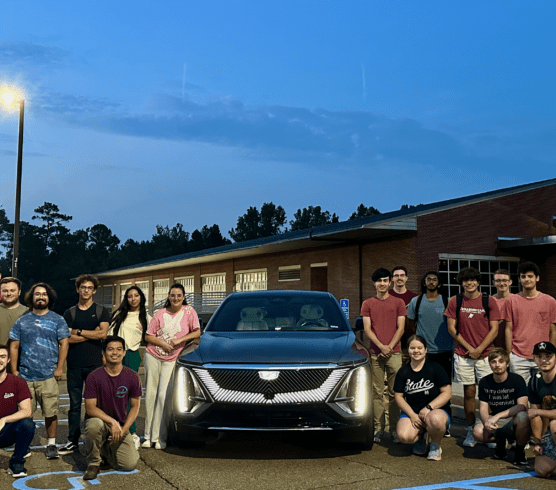

We are extremely fortunate to have access to the facilities at Mississippi State University’s Center for Advanced Vehicular Systems. Our team would not be able to accomplish what we have in the past without these resources. MSU EcoCAR students are able to gain valuable real-world experience in a facility that focuses on safe work practices and innovative technology. We are excited for you to see our workspace and hope you enjoy the tour of our Crib!