Written by Malea Fernandes

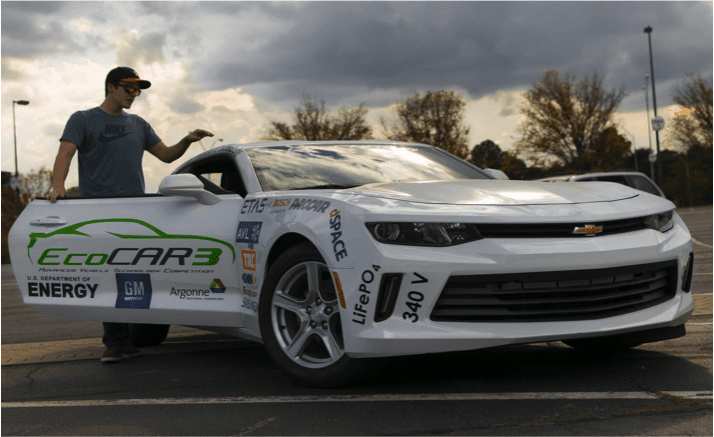

In their fourth year of competition, the Georgia Tech EcoCAR 3 team has made substantial improvements. Since Year One, the team has challenged themselves to learn from their mistakes, improve performance, integrate innovative design systems, and increase efficiency. During Year One, Georgia Tech landed in 15th place but since then has improved, climbing to an overall 3rd place during Year Three. The team also received three first place trophies for ADAS evaluation event, controls and SMS presentation, and mechanical presentation.

This year the team is focused on improving their statistics and testing results from Year Three. Through extensive research, analysis, and testing, the team has reduced their acceleration time. During last year’s competition, the Georgia Tech Camaro recorded a 0-60 mph acceleration rate of 7.2 seconds. Since returning from competition, Georgia Tech reduced their acceleration time to 5.9 seconds by making modifications to their rear differential and optimizing their controller’s torque command strategy. The team is working to verify their vehicle’s reliability by performing extensive testing each week.

In designing their hybrid Camaro, the Georgia Tech team kept cost in mind. They wanted a vehicle that was affordable for the ideal consumer, while still being thrill behind the wheel. One aspect that keeps the vehicle affordable is the use of an off the shelf transfer case to attach the electric motor to the driveshaft. An original transfer case consists of two outputs and one input for the vehicles main source of power to be transported to the vehicle’s front and rear wheels; it is typically used for vehicles that are all-wheel drive. Georgia Tech modified their transfer case to consist of two inputs and one output, allowing for the Camaro’s two sources of torque (engine torque and electric motor torque) to be combined and delivered to the rear wheels. The use of a transfer case keeps the team from having to build a custom gearbox for electric motor integration; this simplifies the design process and lowers the cost of the vehicle.

In addition to making the car fun and affordable, the controls and innovation teams are working to improve fuel efficiency. The Georgia Tech Innovation team is using machine learning techniques to predict the driver’s future intention. The controls team uses these predictions to modify the vehicle’s operation which will increase fuel economy, reduce emissions, improve drivability. The different hybrid modes of operation are determined by an Equivalent Consumption Minimization Strategy (ECMS). ECMS is a unique controls strategy that determines which hybrid mode of operation should be selected based on a weighted cost assigned to using mechanical or electric energy. The hybrid modes of operation include engine only, electric motor only, blend of engine and electric motor, regenerative braking, or engine charging. By carefully selecting the most optimal mode of operation, the team vehicle should achieve a combined 30 MPGGE (miles per gallon gasoline equivalent), 27 MPGGE in city driving conditions, and 34 MPGGE in highway driving conditions.

The Georgia Tech is enthusiastic about their progress throughout the competition. Through these innovative design changes, the team is eager to continue developing and testing the vehicle in preparation for this year’s competition.