By Em Jankauski

The final year of the Battery Workforce Challenge is nearly underway. A new year means new introductions. Meet Jon Darrow — the newest BattChallenge Executive Steering Committee member and Stellantis’ vice president of propulsion systems for its North America Technical Centers.

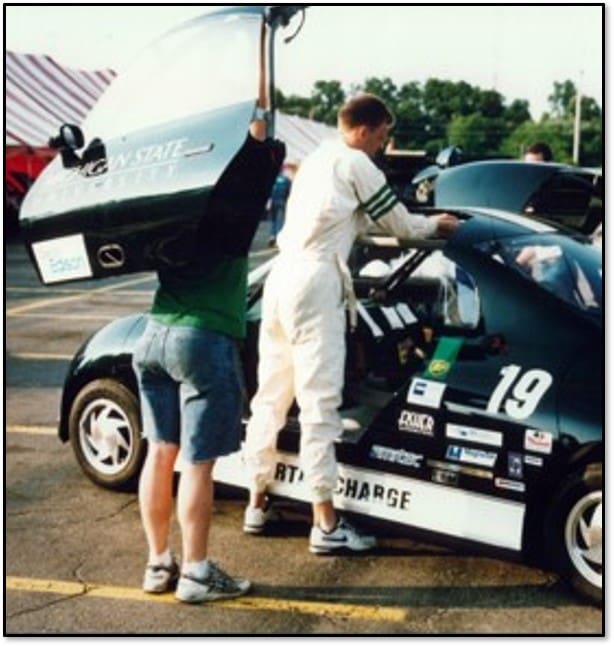

Darrow may be new to the BattChallenge, but he’s no stranger to the Advanced Vehicle Technology Competitions family, having been involved in the 1993-94 series known as the Hybrid Electric Vehicle Challenge.

He holds both bachelor’s and master’s degrees in mechanical engineering from Michigan State University. But his interest in engineering all started as a youngster at his family’s Fort Fudge Shop candy store in Mackinaw City, Mich., where he was captivated by a mechanical 1950s saltwater taffy wrapping machine.

“This machine would take 80 pounds of bulk taffy and reduce it down to size, cut the taffy, cut the paper and wrap the candy in the paper,” Darrow said. “It did this with a single motor and gear, cams and chains — no software or electronics. I became a mechanical engineer. The business is still using that same machine today in Mackinaw City making taffy.”

Darrow passed out saltwater taffy to BattChallengers earlier during his May debut at the BattChallenge’s Year Two Competition Plenary Session.

His involvement began earlier in March when he was promoted to Stellantis’ vice president of propulsion systems, and the BattChallenge fell under that role.

“I’m excited (to have the) opportunity to support this project,” Darrow said.

His first impression of the BattChallengers?

“(They’re) motivated, very intelligent and eager to learn,” Darrow said. “Most impressive is (their) ability to jump into such a project and learn as they go, keeping a positive attitude and working through issues.”

Let’s catch up with Darrow in a fun Q&A and see what his perspective is on the BattChallenge so far. Without further ado, here’s Darrow.

***

Q: How do you hope you hope to make an impact in the BattChallenge ?

A: “I hope to make impact on leadership, decision making where needed and motivation. I hope I can set an example of a prior AVTC alum. I can provide insight to the automotive industry and be a reference for directions related to the students and their journeys.”

Q: As an AVTC alum, what advice do you have for current BattChallengers to make the most of their time in the competition?

A: “The best advice I have is to balance the work and school (as) it will be a challenge to package it all in.

“The benefits and the learning you get from the BattChallenge will be beneficial for getting your first job and also a step ahead on your learning. School is the reason you are there, but a perfect GPA is not always the answer. A well-balanced employee is what I am looking for. Being able to balance school and work to excel at both is the key.”

Q: As an AVTC alum, how critical is it for university and vocational students to get hands-on experience with OEMs’ vehicles before entering the industry?

A: “I am a hands-on engineer, (and) it has served me well. In my opinion, it is very critical for anyone in the auto industry. We sell cars and trucks that people use in everyday life. Our customers have a level of expectation that when they buy a vehicle it works, and we do that by being involved in the parts.

“We do this by testing and working directly with the parts. The hands-on approach accomplishes this. Even in areas like software, you need to know what your software actuates or measures. Hands-on work gives another dimension to the speed at which engineers operate.”

Q: How is the BattChallenge beneficial to Stellantis and the RAM brand?

A: “The benefit we get from the BattChallenge is an amazing workforce ready to start work. (Students will) have learned that failure is OK, and working and finding solutions is part of the job. They learn to work in teams and find compromise where needed. The people are the key to success for any company and finding employees with a head start on this is key to success.”