By Cathy Wang and Michelle Cai / The Ohio State University

In the Battery Workforce Challenge, collaboration with industry leaders is essential in preparing the next generation of engineers for the future of electrics and automotives. One of the key sponsors, Eeaton, is making a significant impact by providing advanced technology and products to improve battery pack performance and safety.

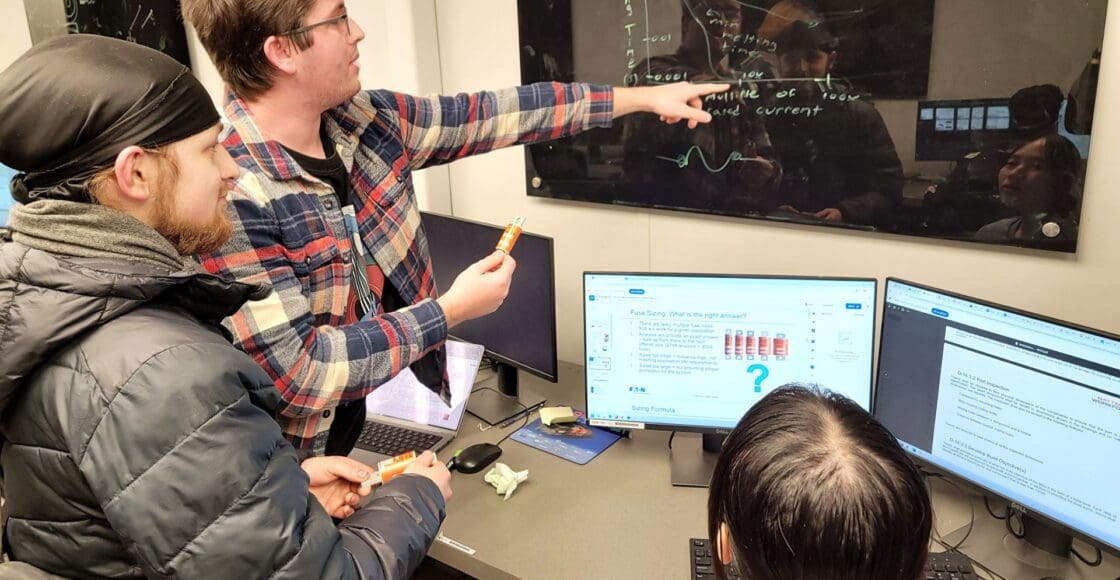

During the year two fall workshop, Eaton hosted an information session, offering detailed information about its Breaktor® technology. The team received a great deal of insight and inspiration regarding the hardware’s unique configuration and opportunities with electrical controls. Eaton also provided important guidance on diagnostics and thermal modeling for our design. This deep insight prepared the team with the knowledge needed to implement this technology effectively.

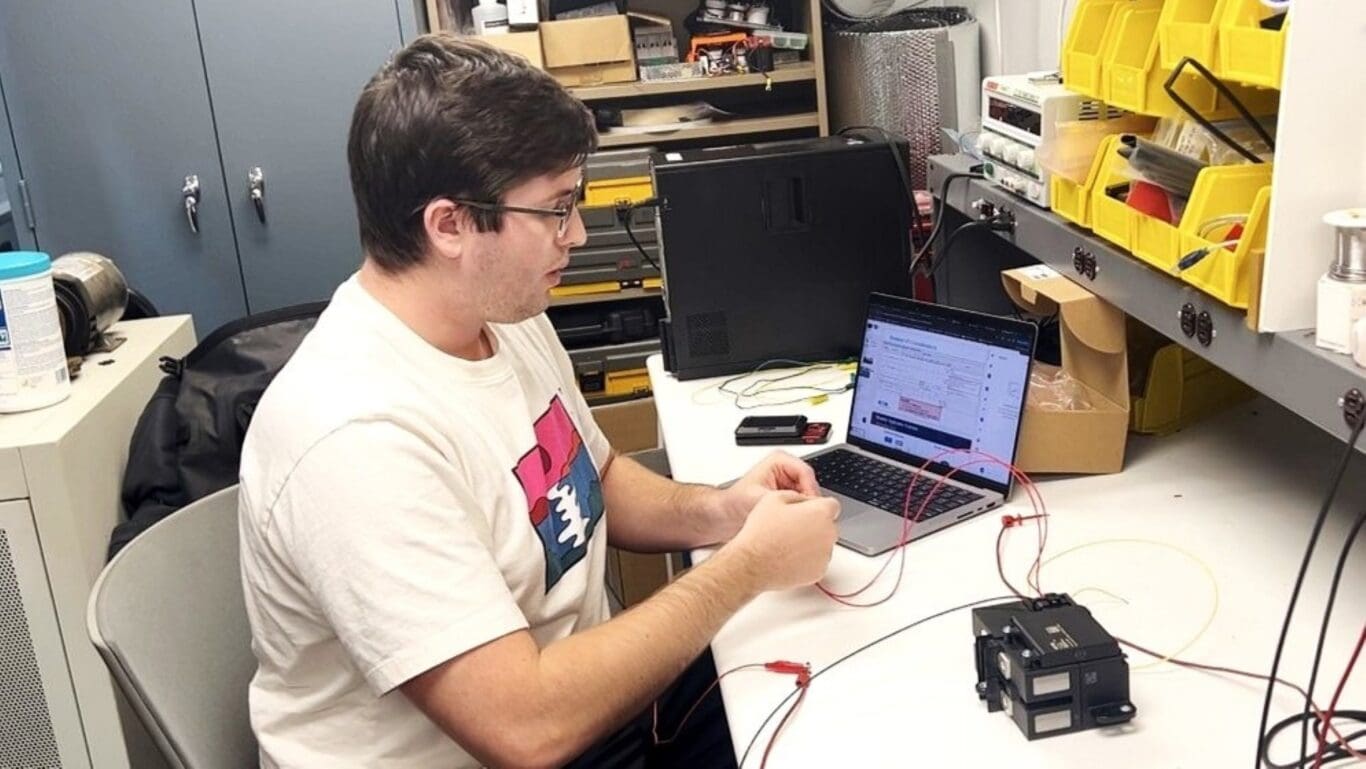

Our team is actively integrating Breaktor® technology into the battery disconnect unit, ensuring that the system meets the safety standards. During this process, the team’s electrical hardware team has been collaborating closely with experts from Eaton, learning from its knowledge and applying best practices in circuit protection. Additionally, software team members are developing control strategies that optimize how the Breaktor® interacts with the battery management system. By working with this innovative product, the team can develop a deep understanding of fault detection, circuit safety and overall energy management in the EV design.

In addition to the Breaktor®, Eaton also offers a Fuse Sizing 101 session, where it introduces the fundamentals of fuses and provides critical knowledge on selecting the optimal fuse sizes for the team’s BDU design.

Understanding fuse selection for our team is essential for ensuring proper circuit protection and preventing electrical failures in the battery pack. With Eaton’s support and the provided fuses, members gain critical knowledge to effectively apply fuses to the BDU design.

Eaton’s support on the products provides great opportunities for the team members to familiarize themselves with the components, and it enables the team to apply it to real-world applications. Through the workshop, informative session and office hours, the team could directly engage with Eaton’s engineers and industry professionals, gaining valuable insights and knowledge from real-world cases. Moreover, the more the team engages with experts from Eaton, the more appreciation arises for how the industry contributes to the innovation and safety in the EV systems.

Safety is always the top priority in any EV system, and the Eaton’s Breaktor® and fuses play critical roles in elevating the protection of the team’s BDU design. By collaborating with Eaton and integrating those technologies, the team is making a significant step toward a safer battery system, bringing the team closer to achieving the performance and safety goals in the Battery Workforce Challenge. The team is extremely grateful for Eaton’s continued support, and it looks forward to showcasing the impact in the final design.

Educators, industry leaders, and students are encouraged to continue supporting such collaborations, innovations and excellence in EV technology. To stay updated on the progress and future collaboration, follow the team on Facebook, Instagram and LinkedIn.