By Andrew Lambrecht, Clemson University

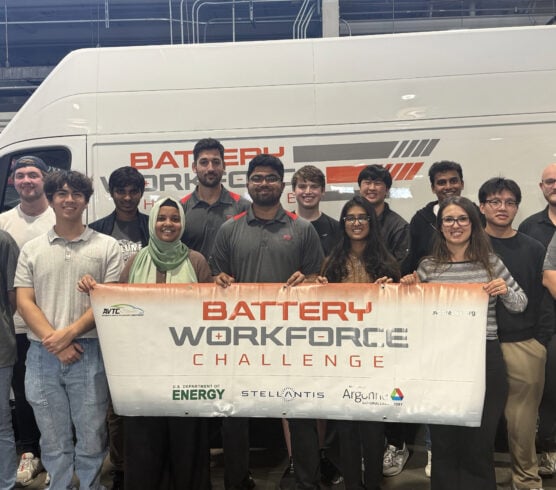

The spring 2025 semester has been exciting for all participating schools in the Battery Workforce Challenge. The Clemson University & Greenville Technical College’s team has been working rigorously to progress the development of its EV battery pack. The two schools displayed their joint progress in late February during the winter workshop right in their home city of Greenville, S.C.

While at the workshop, the teams received their blank canvas to work on: Stellantis’ RAM Promaster EV. The van is a real-world foundation for students to design the next generation of high-voltage battery systems.

Working on the project is now incredibly different for the Clemson and Greenville Tech students, having the electric van in-person at their facility. For two years, the Clemson University & Greenville Tech team has been preparing for this moment — from running simulations, devising theories and using the resources team members had. But now, they have the canvas to implement the technology into.

“Now we have the real vehicle that lets us do whatever we’ve done so far and implement it in the vehicle,” said Saroj Paudel, Clemson University doctoral student and the team’s engineering manager.

Working on such a vehicle will change the fabric of the project. But it’s also an incredible opportunity to get hands-on experience with a delivery vehicle of the future. Electric delivery vans are set to change much of the last-mile delivery sector.

“All of us have these vehicles in our neighborhood every day,” said Micky Bly, Stellantis’ senior vice president and head of global propulsion systems. “By making them electric, it’s just a different way of thinking about how this electric vehicle movement can go forward.”

The RAM Promaster EV is a vehicle that helps reduce carbon, improve efficiency, and reduce the reliance on fossil fuels. By going electric, they also cut down on noise and lower maintenance costs.

Equipped with a 110-kWh battery pack, the RAM ProMaster EV offers up to 164 miles of range and fast-charging capabilities. Most fleets will likely charge up during idle times and have a full battery ready for their daily shifts. Electrifying fleet vehicles just makes a lot of sense. And it’s precisely the kind of vehicle that future engineers and technicians need to understand, inside and out.

Working on the RAM ProMaster EV is not only an excellent opportunity to learn about battery design, but it’s also about being involved with the delivery van of the future.

“This project has been challenging as we’ve gone through obstacles, but it has been exciting to come up with solutions together,” said Terrel Gamble, a Greenville Technical College student and team member. “We cannot wait to get started working on the van. I’m looking forward to seeing what we can accomplish together.”