Written by: Lily Joy Crosby

One of the best parts about EcoCAR is getting to work with our incredible sponsors. Working with them provides our team members the chance to use industry-level tools, giving them the training and skills needed to launch a career in engineering. We know that each of our EcoCAR sponsors is imperative to the work we do as a team, so having the opportunity to partner with them on different team deliverables and objectives is always a great opportunity.

This year Communications Managers were each partnered with a competition-level sponsor to highlight the work they do with our team. Here at Team Tennessee, we were partnered with Siemens. Throughout the collaboration, we worked with Siemens to write an article demonstrating the importance of our partnership with them and how the resources they provide to our team help us find success in the competition.

Leigh Anderson, Business Development Manager at Siemens, said, “Siemens is proud to be a longstanding sponsor of the EcoCAR Mobility Challenge. This year, we had the unique opportunity to collaborate with UT on an article showcasing how teams utilize our products. It was great to see the relationship between our organization and this university grow through this collaboration, and we hope to continue partnerships like this in the future as we continue sponsoring AVTCs.”

For more than a dozen years, our team has relied on Siemens software to advance the technology in our hybrid vehicles through their sponsorship and dedication to AVTCs. The resources they provide to our teams make them an essential partner of the EcoCAR Mobility Challenge. As one of our Sustaining level partners, they provide us with different training and software that allow our engineering functions to be carried out much more quickly and easily.

The most important, and difficult, part of creating such a complex vehicle system is integration. While designing and creating new ideas each have their own challenges, the integration phase holds the greatest risk and opportunity for error. Team Tennessee is currently operating with nine team leads, 12 undergraduate students, four volunteers, and four faculty advisors. With a limited number of students working on the project, having resources that cut down on time and cost are essential to our success.

With the use of the NX software that Siemens provides to all EcoCAR teams, we were able to save a lot of time and money in the integration stage by testing out different aspects of innovation before implementation into the vehicle.

NX is a design software that can be used for mechanical, electrical or hydraulic pneumatics design. Engineers use the NX software to do strength, aerodynamic, and weight analysis. NX saves time, money, and resources because engineers can do tests in the digital world of NX rather physically testing parts. Engineers create and manipulate the vehicle model in NX in order to ensure their work is accurate and precise before implementing it into the actual vehicle. When moving to the actual vehicle, Teams never have to worry about throwing away parts that do not work because all the parts are designed to work in advance using the NX software.

Christopher Lang, Propulsion Systems Integration Engineering Lead, said about NX, “With Siemens’ NX software, there are unlimited opportunities for innovation. Pretty much anything you want or could want to do, you can do in NX.”

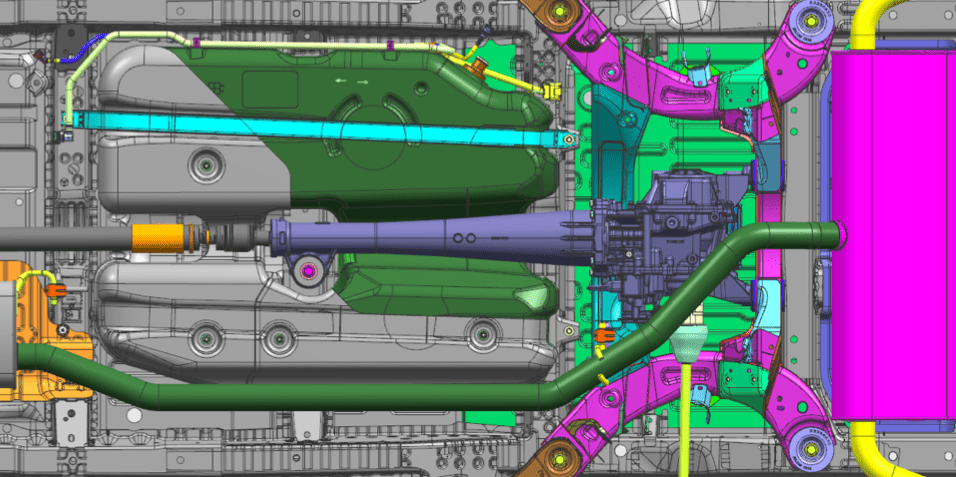

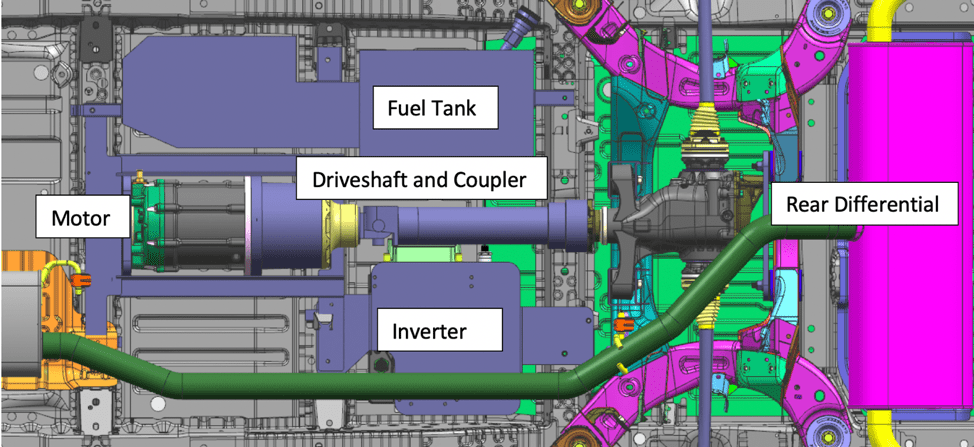

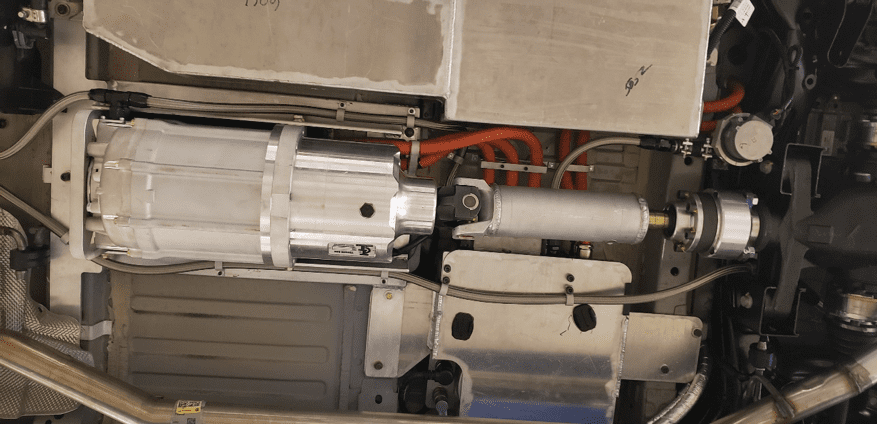

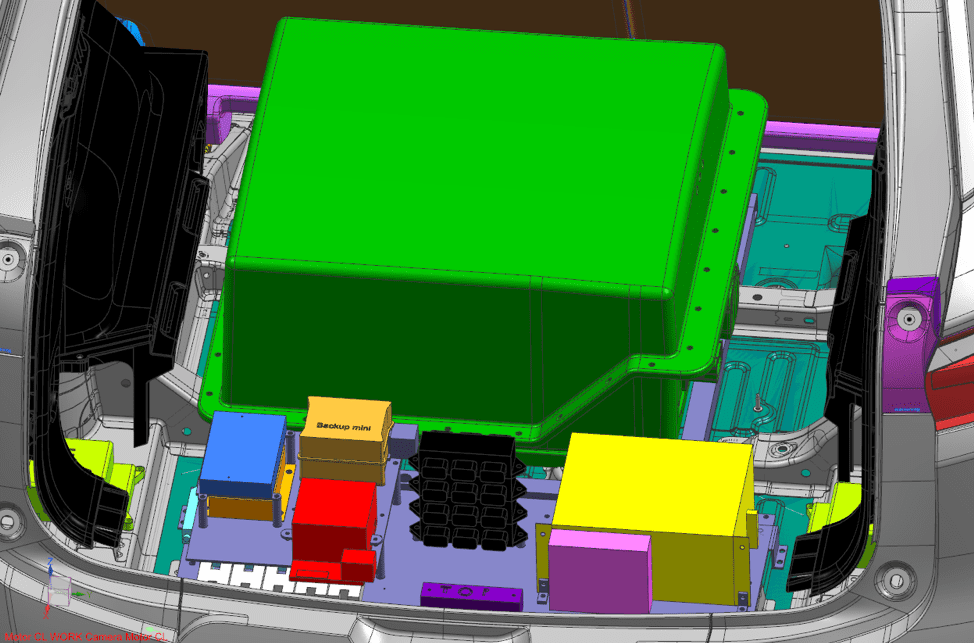

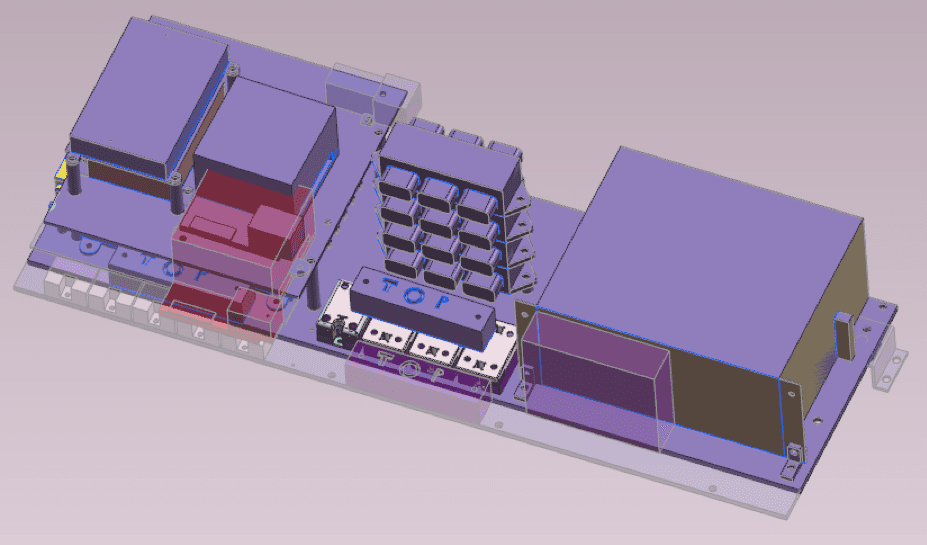

The electric power train integration consisted of the following four main components: 4.5 kWh A123 high voltage (HV) battery, 85 kW TM4 motor and inverter, General Motors differential, and fabricated driveshaft, and motor coupler. To integrate these components, new mounting structures were designed in NX as a “digital twin”. This model was used to create the necessary drawing files to build new parts and make modifications to the vehicle. In one of these modifications, the rear passenger compartment floor was cut, and a patch panel was installed to allow for the motor to sit higher in the vehicle to maintain ground clearance restrictions. By making the digital twin in NX before implementing these changes into the Blazer, the team was able to ensure the accuracy of all permanent vehicle modifications.

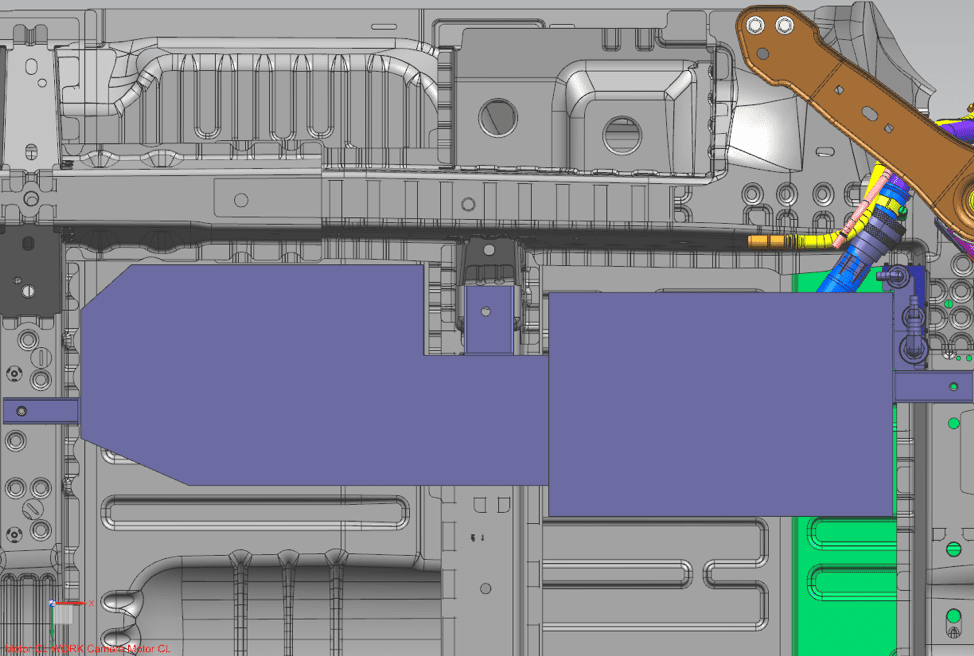

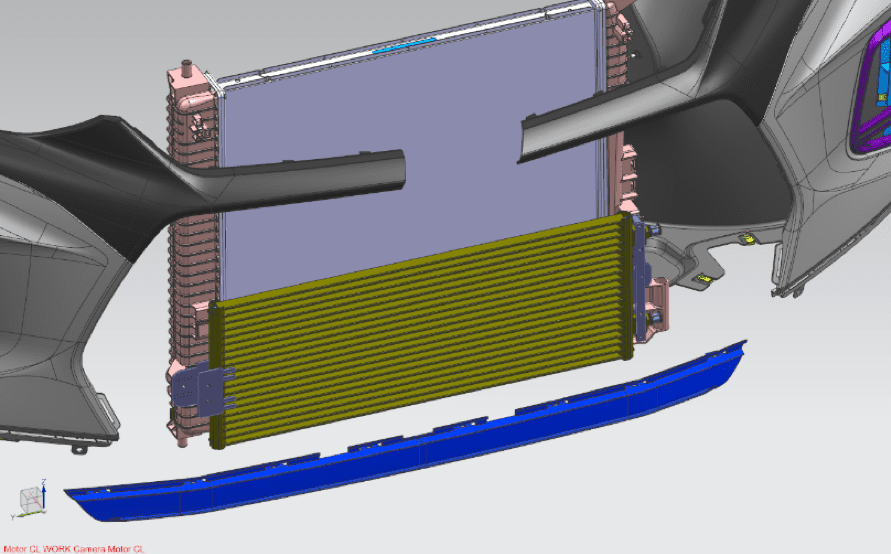

The above NX screenshot demonstrates the various changes that have been made to the vehicle by the EcoCAR team to create the hybrid power integration. The engineers were able to create a new, smaller fuel tank, add the electric drive system (motor, driveshaft, coupler, and inverter), and transfer power from the rear differential to the wheels.

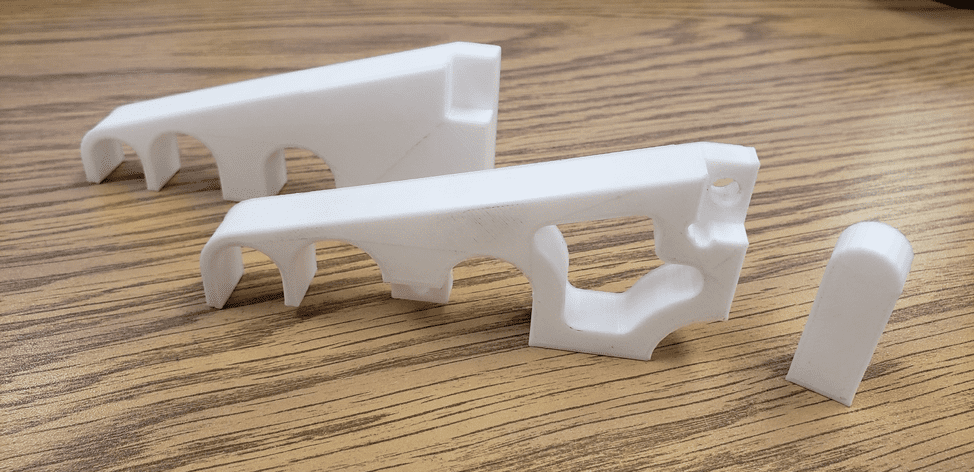

The design process progresses from the digital twin to the physical drawings, which are then 3D printed using their digital part files. Parts are 3D printed to quickly and inexpensively double check their fit on the vehicle, before being machined out of aluminum.

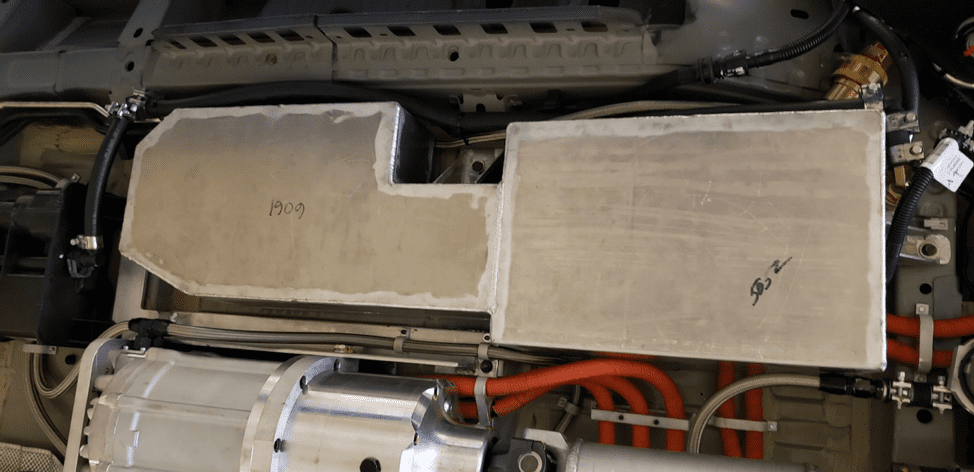

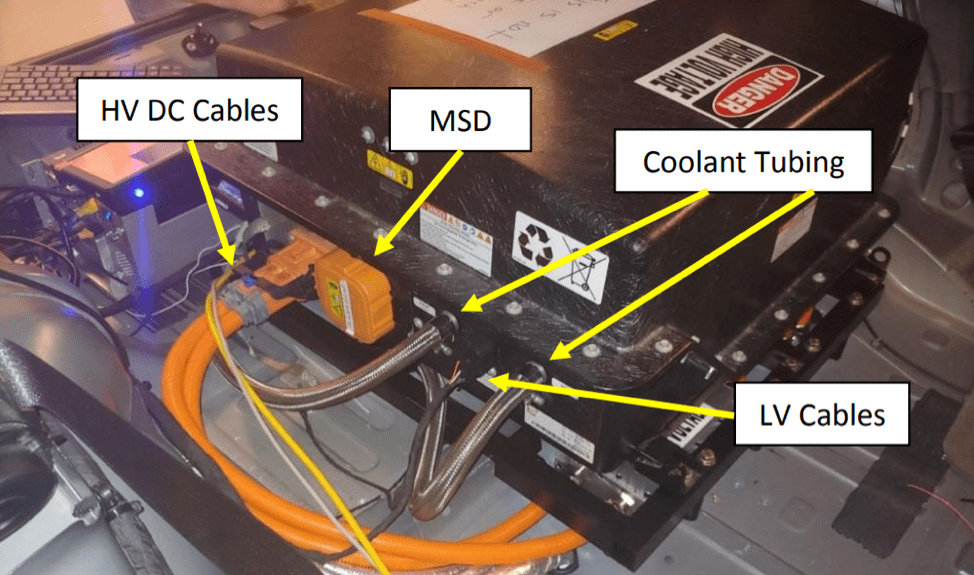

Once the digital twin has been created in NX, and part sizes have been double checked with 3D printed material, our team was ready to make the actual modifications to the vehicle and parts. The above image demonstrates the physical model of this system in the Blazer. Each part that has been implemented was successfully designed and machined without error, thanks to the precision of the NX digital twin.

The smaller fuel tank created by Team Tennessee.

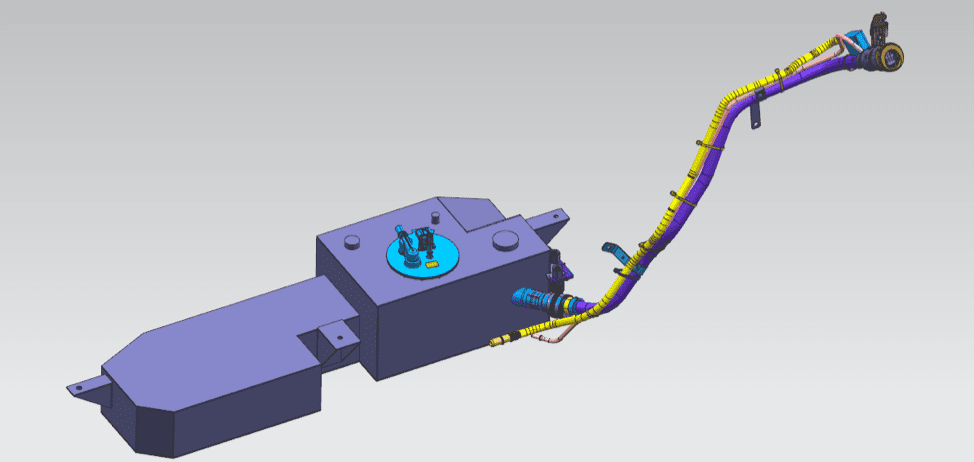

NX was also necessary for Team Tennessee’s fuel tank integration. The vehicle’s stock fuel tank had to be removed to make space for the electric propulsion system integration. The team manufactured and built a smaller fuel tank and placed it into the car using some of the stock mounting locations. Since the engineers were using NX software, the new fuel tank was designed and made to reuse the stock fuel filling components. The above photo demonstrates how the new fuel system was integrated into the stock fuel system.

Again, the NX software allowed engineers to create all changes digitally before implementing them physically into the car. As is demonstrated in the images above, the digital twin captured the dimensions of the car and allowed engineers to successfully implement their designs on the first try.

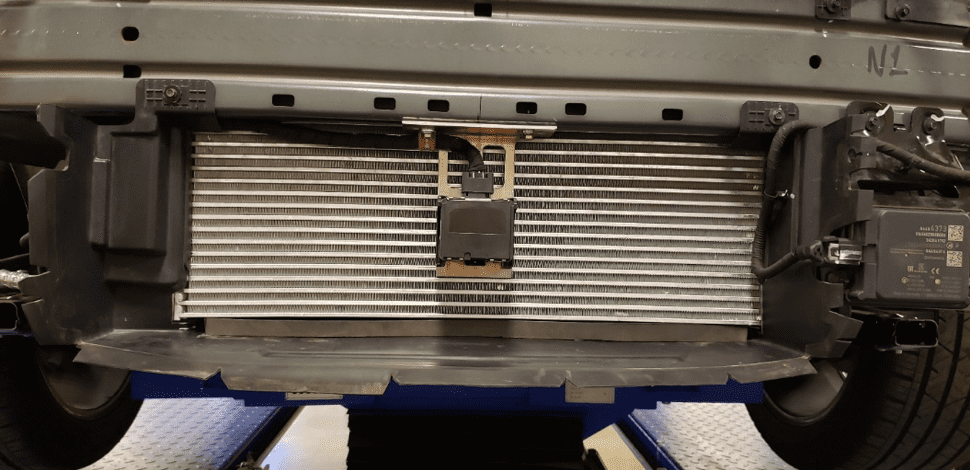

Another necessity in hybrid electric vehicles is a high voltage (HV) cooling system. In the Blazer, there are two stacked radiators. One is the stock vehicle system and the other is an additional HV cooling system that was added by our engineers to cool the electric HV components which are used in our hybrid vehicle. The motor, inverter, and battery are cooled with this independent cooling system. This cooling system was integrated in front of the stock radiator, and the cooling line routing was done in NX to allow the correct lengths to be used in the system. NX also allowed our engineers to add the mounting hardware needed to adequately retain the lines.

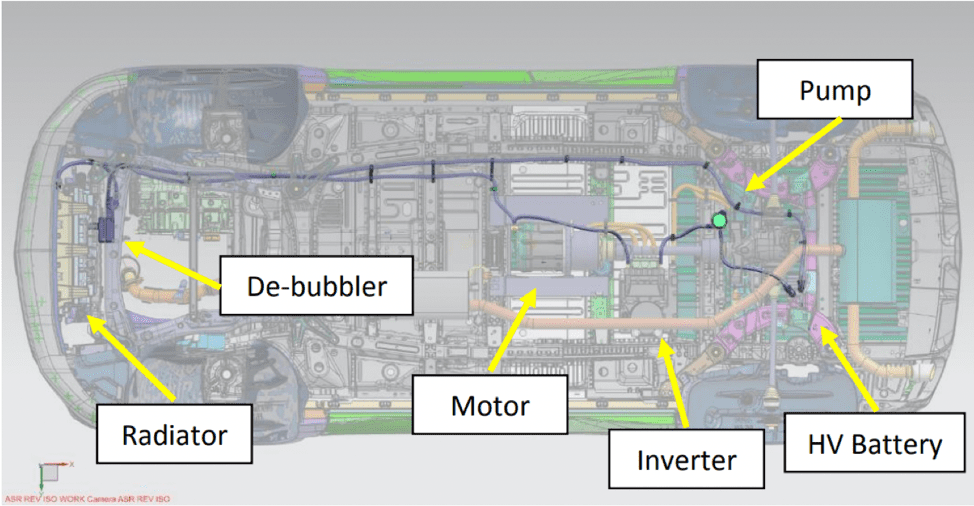

The above image captures the routing of the HV cooling system created in NX. Engineers digitally routed tubes to get the lengths of them so that they could integrate properly sized coolant lines into the system. This picture demonstrates the various fittings and mounting hardware and the locations of the various high voltage components and cooling loop components including the pump, de-bubbler, and radiator.

Engineers also use NX for the electrical system and for CAVs purposes. The motor, inverter, battery, and power distribution boxes are all interconnected to provide propulsive power to the rear of the vehicle. The phase cable, HV cables, and mounting structure were developed in NX to accurately represent their integration into the vehicle. The HV battery, energy storage system (ESS) and CAVs equipment must all be integrated into the rear of the vehicle. By creating the digital twin in NX, mounting structures were able to be implemented for each of the various components that allow them to be safely integrated into the vehicle.

Since EcoCAR is dealing with such innovative and new technologies, sometimes competition rules are updated in order to ensure proper safety measure are taken. In this year’s EcoCAR challenge, there was an adaptation made to the rear vehicle systems integration for this reason. New specifications were made to create a crush zone for the rear of the vehicle in case of a rear-end collision. This was done so that if a rear-end collision occurs the CAVs equipment will not be pushed into the battery.

The NX software allowed our team to develop strategies to comply with the new rules without destructive testing. These strategies allowed our team to quickly change these components that were already integrated into the vehicle without causing major disruptions in testing. All changes were made in the digital twin and then implemented easily into the vehicle.

Project Manager JP Nelms, said, “NX is truly amazing. You can test anything in a model before you make it. It is incredibly accurate, and it saves valuable time and money. NX makes it possible for us to compete on the same level as other teams that may have more resources.”

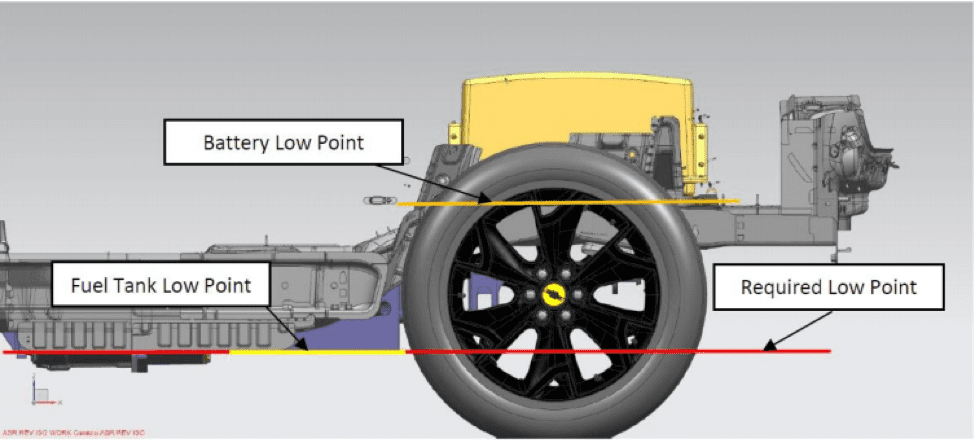

There are also other specifications that teams are required to abide by, such as ground clearance. There are specified low points for the fuel tank and battery. Since our team can do this in NX before it is implemented into the vehicle, we can ensure we pass all the criteria before actually building these structures and components. Without NX, it would be incredibly difficult to modify vehicles into hybrid-electric vehicles. This software makes it possible to precisely design components and put them in a digital model of the stock vehicle.

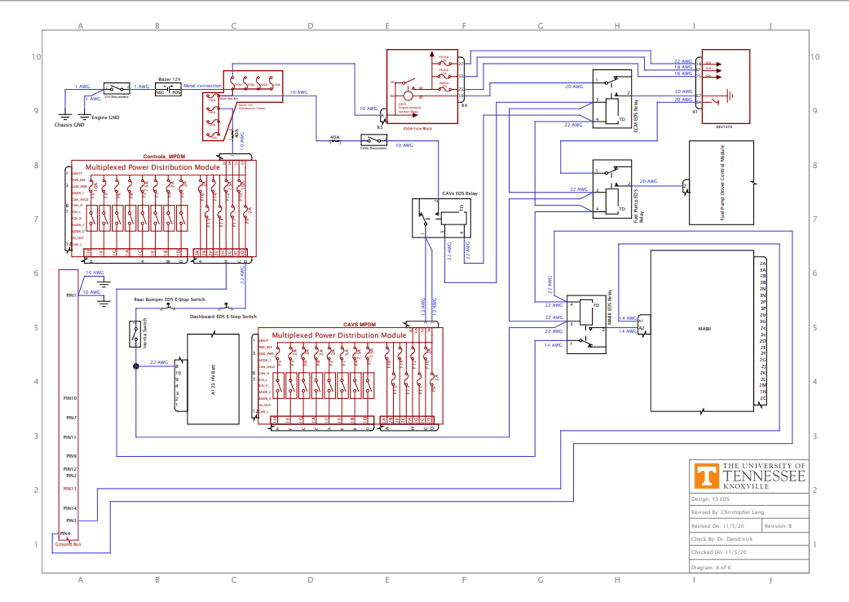

Another helpful software Siemens provides teams is the VeSys software. VeSys is an electronics software that allows teams to document the modifications that have been made to the vehicles stock wiring, electrical harness, and electrical systems. Our team uses VeSys to track changes that have been made and to check the implemented wiring if problems arise. This schematic is very important to the safety of team members. It depicts the circuit which cuts power to the vehicle’s propulsion systems in case of an emergency. While VeSys has premade components such as fuses, switches, and relays, the symbol library and symbol editor allow the team to create various specific electrical components. The most complex components are able to be drawn by the team using the pre-built parts such as fuses, switches, and other diagram components.

UT’s Undergraduate Research Assistant, Landon Harris said, “With VeSys, we can easily organize diagrams and harnesses for the entire car in one project. Better yet, with the higher quality and new features of VeSys documents and reports, our team has even started creating real wiring diagrams before creating the physical wiring…rather than the other way around. Once you’ve used systems like this, you don’t want to go back. I can’t imagine doing this work without the help of Siemens software.”

We at Team Tennessee were glad to highlight this incredible partnership through our sponsor collaboration deliverable. This year’s goals include implementing longitudinal adaptive cruise control and refining our fully integrated propulsion system. None of this could be achieved without our partnership with Siemens. The resources they provide are what make this level of innovation possible as we work toward the future of safer, more environmentally friendly advanced vehicle technology.