By Colten Kristie

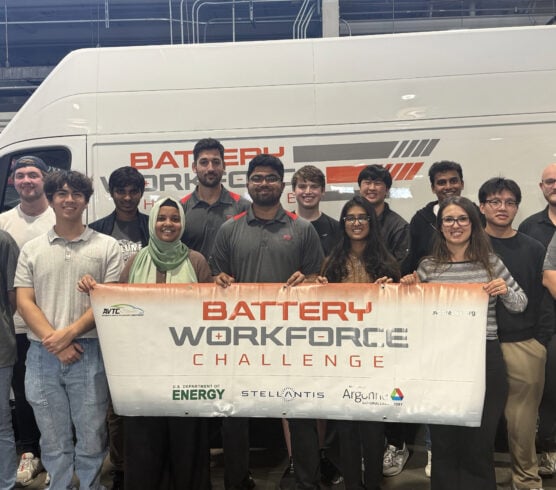

Shortly after the Colorado School of Mines & Arapahoe Community College’s Battery Workforce Challenge team’s return from the winter workshop, held from March 7-9 in the Detroit metro area, the crew continued to nurture its relationship between its university and vocational partners.

The Colorado School of Mines’ university liaison and the Arapahoe Community College faculty collaborated to make an EV Safety Training suited the needs of the engineering students at the Colorado School of Mines as the team began to develop the battery pack.

This was a useful opportunity as it gave the Colorado School of Mines students a chance to learn about a topic outside of their realm of expertise. For the ACC students, it was a chance to transfer their extensive knowledge on vehicle service to their university partners. Overall, safety is a top priority on the Colorado School of Mines & Arapahoe Community College’s BattChallenge team, and the opportunity to develop an understanding of the hazards that come with high voltage battery systems and the actions that can be taken to mitigate these risks are critical to its success.

The training that Jake Tipsword, the vocational faculty member for the Colorado School of Mines & Arapahoe Community College Battery Workforce Challenge team, a faculty member at Arapahoe Community College’s Automotive Technology program, and Peyton Crenshaw, the university liaison for the Colorado School of Mines & Arapahoe Community College’s BattChallenge team and a student at Arapahoe Community College, formulated for the Colorado School of Mines students shared the primary causes of injury when working on EVs, actions that can be taken to avoid injury, and how to determine the proper workflow to ensure safety of those working on the vehicle.

Tipsword and Crenshaw then facilitated a hands-on training. Colorado School of Mines students disconnected the high-voltage interlock loop on the Nissan Leaf. While not required for service of this type, the students practiced using certified CAT3 high voltage personal protective equipment to gain experience in checking and using their gear.

The Colorado School of Mines & Arapahoe Community College team has a proven track record of integrating its crew through valuable hands-on experiences like these. In this developing age of EVs, safety and proper equipment usage are critical for all technicians and engineers.

Safety trainings serve as a vital reminder to all teams about the need to prioritize the wellbeing of both individuals and tools within their work environments. Receiving training on workflow of operations on EV service will also ensure that the team’s engineers develop its battery system in such a way that prioritizes the pack being serviceable by design.

Click here to learn more about the Arapahoe Community College Automotive Technology department.