FutureTruck

Background

In the early 2000s, the demand for light-duty trucks, sport utility vehicles (SUVs), and vans posed opportunities and challenges for the automotive industry. In response to this demand, General Motors and Ford Motor Company teamed up with the U.S. Department of Energy to create FutureTruck.

FutureTruck was a five-year competition (1999-2004) that challenged student engineers to redesign a full-size SUV to meet the needs of efficient transportation, while maintaining performance, utility, and affordability. FutureTruck helped to redefine the ways in which private industry, academia, and government could work together to overcome obstacles of fuel efficiency.

During the first two years (1999-2001), 15 North American universities modified a 2000 Chevrolet Suburban using cutting-edge technologies such as fuel cells and other advanced propulsion systems and alternative fuels. Vehicles underwent extensive testing in more than a dozen technical events including emissions and fuel economy, braking and acceleration, trailer tow, off-road and handling, and static oral presentations. During the 1999-2000 competition, teams were hosted at General Motors Desert Proving Grounds in Mesa, Arizona. In the final year of the General Motors sponsored competition (2000-2001), teams traveled to General Motors Milford Proving Grounds in Milford, Michigan for dynamic testing before heading to Washington, D.C. for the finale event.

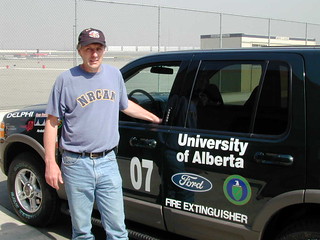

Starting in Fall 2001, 15 universities joined forces with Ford Motor Company and the U.S. Department of Energy to compete in the second phase of FutureTruck. Several previous schools remained from the first phase; however, all 15 universities involved received a mid-size Ford Explorer to re-engineer into a hybrid vehicle. The teams once again had to employ cutting-edge technologies including fuel cells, lightweight materials, and alternative fuels, into their hybrid electric vehicle design strategy.

Students traveled to Ford’s Arizona Proving Grounds in Yucca, Arizona for the 2001-2002 competition. The teams then traveled to California for emissions testing at the California Air Resources Board and dynamic vehicle testing at the California Motor Speedway. The awards ceremony was hosted in Los Angeles.

For a change of scenery, the teams traveled to Ford’s Michigan Proving Ground in Romeo, Michigan and Ford’s Allen Park Test Laboratory for the 2002-2003 competition. The competition culminated in conjunction with Ford’s Centennial Anniversary at Ford World Headquarters in Dearborn, Michigan.

In the final year of FutureTruck (2003-2004), the universities once again were hosted at Ford’s Michigan Proving Ground and Allen Park Test Laboratory for dynamic testing. Teams completed a road rally through Detroit and held a finish line ceremony at Ford World Headquarters.

The groundbreaking four-year competition (2004-2008) gave 17 universities in North America an opportunity to participate in hands-on research and development with leading-edge automotive propulsion, fuels, materials, and emissions-control technologies.

During the competition, students were challenged to re-engineer a 2005 Chevrolet Equinox to minimize energy consumption, emissions, and greenhouse gases while maintaining or exceeding the stock vehicle’s utility and performance. Using a development process modeled after GM’s Vehicle Development Process, teams gained valuable experience in real-world engineering practices. Participating teams were provided with a variety of resources to help achieve their objectives, including technical support and mentoring from General Motors and other sponsors. Each team also received $10,000 in seed money and were eligible to receive additional production parts, software, and hardware from competition-level sponsors.

Year One (2004-2005) focused on modeling, simulation, and testing of the advanced powertrain and vehicle subsystems selected by each school. Students used computer-based math modeling tools to objectively compare and select the advanced technologies to be used for their overall design. Teams also developed and used rapid prototyping and hardware-in-the-loop (HIL) tools to validate their models and control systems. The Year One competition was held at GM University and GM’s Milford Proving Grounds, where teams showcased their design efforts.

During Year Two (2005-2006), teams developed and integrated their advanced powertrain and subsystems into the donated vehicle. This year was often dubbed the ‘mule’ vehicle build year since teams had to get to a 65% buy-off stage. The year-end competition was held at General Motors Desert Proving Grounds in Mesa, Arizona and featured an extensive set of vehicle dynamic events including braking, handling, acceleration, fuel economy, drive quality, and trailer towing performance. Teams were also judged through technical design presentations and written reports.

In Year Three (2006-2007), teams had to refine their advanced vehicles into a showroom-ready vehicle. At the end of the academic year, teams traveled to General Motors Milford Proving Grounds in Milford, Michigan for dynamic vehicle testing. Much like in Year Two, teams had the chance to compete in several dynamic events like braking, accelerating, dynamic handling, and drive quality. The awards ceremony was held at General Motors Renaissance Center in downtown Detroit, Michigan.

The fourth and final year of Challenge X (2007-2008) featured additional refinement, as well as expansive outreach and media efforts throughout the community. The year began with a road rally through Los Angeles and a ride and drive at the Electric Vehicle Symposium 23 in Anaheim, CA in November 2007. In addition, teams showed off their vehicles to Jay Leno at his garage in Burbank, CA. Teams then had several months to refine their vehicle before taking part in vehicle testing at the Old Bridge Township Raceway in Englishtown, New Jersey in May 2008. After testing, teams began a three-day East Coast Road Rally, which began in New York City with a media event. Teams then made a stop in Baltimore for an education day, and then concluded at the U.S. Department of Energy in Washington, D.C.

Throughout the four years, students developed a strong understanding of advanced vehicle technologies that prepare them to become highly skilled engineers in the automotive industry and remain competitive in the global marketplace.

FutureTruck

FutureTruck

FutureTruck

FutureTruck

FutureTruck

FutureTruck

FutureTruck

FutureTruck

FutureTruck

Inovations & Hightlights

The teams in FutureTruck employed many novel ideas, approaches, and technologies that provided solutions to increase the efficiency and reduce the overall environmental impact of SUVs. Various hybrid electric vehicle designs were demonstrated by the student-modified vehicles, including series and parallel hybrids and fuel cells.

Over the course of five years, engines were modified to run on bio-based fuels like ethanol and biodiesel, as well as homogeneous-charge compression ignition engines and hydrogen fuel cells. Teams combined these advanced power units with emerging exhaust gas after-treatment technologies to reduce emission and greenhouse gas production. Other systems, such as selective catalytic reduction, to control oxides of nitrogen emissions, were used with high efficiency diesel engines. Advanced electric drive systems enabled hybrid features such as regenerative braking, high load assist, and transient smoothing to improve vehicle-level efficiency.

- Fourteen of the 15 vehicles were able to run their modified Ford Explorers during the 2002 competition.

- The University of Wisconsin-Madison achieved 21.85 miles per gallon gasoline equivalent, which was a 45% increase.

- Three vehicles qualified as an Ultra-Low Emissions Vehicle (ULEV) during emissions testing in 2002.

- Texas Tech was the first FutureTruck team to compete in the On-Road Fuel Economy, Acceleration, and Off-Road events under hydrogen power.

- Teams included several emission reductions technologies, including diesel after-treatments like urea, EGR coolers, and titanium exhaust systems.

- Seven teams obtained better fuel economy than the control vehicle in 2002, this increased to eight teams in 2003.

- University of Tennessee, Knoxville used wind tunnel testing to implement a front air dam and a rear spoiler to improve their vehicle’s coefficient of drag.

- University of Idaho has created the world’s first Tri-brid, combining hydraulic, ultracapacitors, and a combustion engine in one vehicle.

- West Virginia University utilized urea injection which was performed upstream of the SCR catalyst to further reduce oxides of nitrogen (NOx) emissions.

- Teams included modeling simulations, advanced control systems, and telematics into the program.

- Ten of the teams completed the trailer tow event, demonstrating that they were capable of towing a 2,000-lb trailer at varying speeds for approximately 15 miles including a short 17% grade.

- Michigan Tech accelerated in 11.238 seconds, beating the stock vehicle’s time in 2002, and Georgia Tech beat this in 2003 with 10.88 seconds.

Universities Involved

Cal Poly, San Luid Obsipo

Location

San Luis Obispo, CaliforniaFaculty Advisors

- Dr. Chris Pascual

- Dr. Brian Higgins

- Dr. George Delgrammatikas

Georgia Institute of Technology

Location

Atlanta, GeorgiaFaculty Advisors

- Dr. Jerome Meisel

- Dr. Caryn Riley

- Boyd Pettitt

- Gail Palmer

Ohio State University

Location

Columbus, OhioFaculty Advisors

- Dr. Yann Guezennec

- Dr. Giorgio Rizzoni

- Dr. Gregory Washington

- Frank Ohlemacher

- Lino Guzzlla

Pennsylvania State University

Location

University Park, PennsylvaniaFaculty Advisors

- Dr. Donald Streit

- Dr. Heath Hofmann

- Joel Anstrom

- Dr. Dan Haworth

Texas Tech University

Location

Lubbock, TexasFaculty Advisors

- Dr. Timothy Maxwell

- Dr. Daryl Vines

- Dr. Michael Parten

University of Idaho

Location

Moscow, IdahoFaculty Advisors

- Dr. Steve Beyerlein

- Dr. Don Blackketter

- Dr. Dean Edwards

- Frank Albrecht

University of Tennessee, Knoxville

Location

Knoxville, TennesseeFaculty Advisors

- Dr. Jeff Hodgson

- Dr. William Hamel

- Jeff Freeman

- Dr. David Irick

Winners & Awards

Each year, university teams compete in a variety of static and dynamic events that range from oral presentations to on-road vehicle testing to communications and business tactics. These static and dynamic events are judged by industry sponsors and professionals, both throughout the year and in-person at the year-end competition.

Year One 1999-2000

- 1st Place – West Virginia University

- 2nd Place – University of Maryland

- 3rd Place – Virginia Tech

- 4th Place – University of California, Davis

- 5th Place – University of Wisconsin – Madison

- 6th Place – Ohio State University

- Lowest Greenhouse Gas Emissions – West Virginia University

- Best Trailer Towing Performance – Georgia Institute of Technology

- Best Acceleration – Georgia Institute of Technology

- Best Dynamic Handling – Virginia Tech

- Best On-Road Fuel Efficiency – University of California, Davis

- Lowest Regulated Tail Pipe Emissions – University of Maryland

- Best Technical Report – University of Wisconsin – Madison

- Best Vehicle Design Inspection – University of Wisconsin – Madison

- Best Oral Design Presentation – University of Wisconsin – Madison

- Best Consumer Acceptability – Virginia Tech

- Lowest Vehicle Driving Losses – West Virginia University

- Best Use of Advanced Technologies – Michigan Technological University

- Safety Award – University of Wisconsin – Madison

- Best Appearing Vehicle- Virginia Tech

- Innovations in Aluminum – University of Wisconsin – Madison

- Best Workmanship – University of Wisconsin – Madison

- Best Teamwork – University of Wisconsin – Madison

- Sportsmanship Award (tie) – Texas Tech University and University of Tennessee, Knoxville

- Spirit of the Challenge Award – Michigan Technological University

- Best Off-Road Performance – University of Maryland

- Excellence in Renewable Fuels – University of Maryland

- Best Biodiesel Application – University of Tennessee, Knoxville

- National Science Foundation Outstanding Faculty Award – Glenn Bower, University of Wisconsin-Madison

Year Two 2000-2001

- 1st Place – University of California, Davis

- 2nd Place – University of Wisconsin – Madison

- 3rd Place – University of Maryland

- 4th Place – Georgia Institute of Technology

- 5th Place – Cornell University

- 6th Place – West Virginia University

- Lowest Greenhouse Gas Emissions – Cornell University

- Lowest Regulated Tailpipe Emissions – University of Maryland

- Best On-road Fuel Efficiency – University of Wisconsin – Madison

- Best Technical Report – University of Wisconsin – Madison

- Best Vehicle Design Inspection – University of Wisconsin – Madison

- Best Oral Design Presentation – University of California, Davis

- Best Consumer Acceptability – Georgia Institute of Technology

- Best Use of Advanced Vehicle Technology – Michigan Technological University

- Safety Award – University of Wisconsin – Madison

- Best Trailer Tow Performance (tie) – University of Maryland & West Virginia University

- Best Acceleration – Georgia Institute of Technology

- Best Use of Materials – University of Wisconsin – Madison

- Best Dynamic Handling – Georgia Institute of Technology

- Excellence in Renewable Fuels – Cornell University

- Best Appearing Vehicle – University of Wisconsin – Madison

- 1st Place, Most Innovative Use of Aluminum – University of Wisconsin, Madison

- 2nd Place, Most Innovative Use of Aluminum – Georgia Institute of Technology

- 1st Place, The MathWorks Vehicle Modeling Award – University of California, Davis

- 2nd Place, The MathWorks Vehicle Modeling Award – University of Tennessee, Knoxville

- 3rd Place, The MathWorks Vehicle Modeling Award – Georgia Institute of Technology

- 1st Place, Cisco Systems Telematics Award – University of California, Davis

- 2nd Place, Cisco Systems Telematics Award – Penn State University

- 3rd Place, Cisco Systems Telematics Award – University of Wisconsin – Madison

- Best Off-road Performance – University of Tennessee

- Best Workmanship – University of Wisconsin – Madison

- Best Teamwork – University of Tennessee, Knoxville

- Best Sportsmanship Award – Texas Tech University

- Spirit of the Challenge Award – University of Idaho

- Most Improved Team – Cornell University

- Best Skit – Ohio State University

- National Science Foundation Outstanding Faculty Advisor – Dr. Jeff Hodgson, University of Tennessee

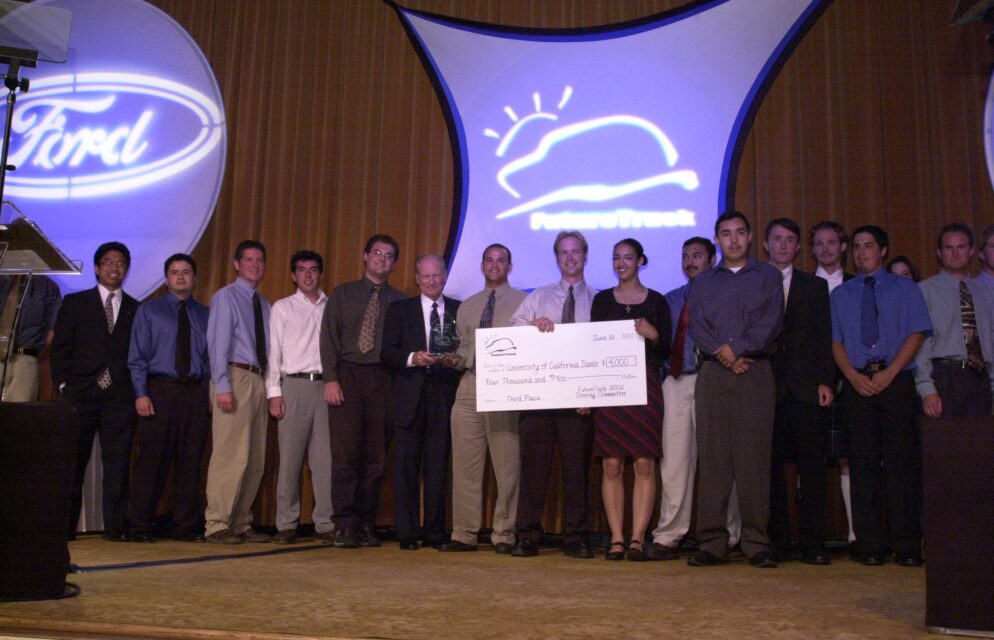

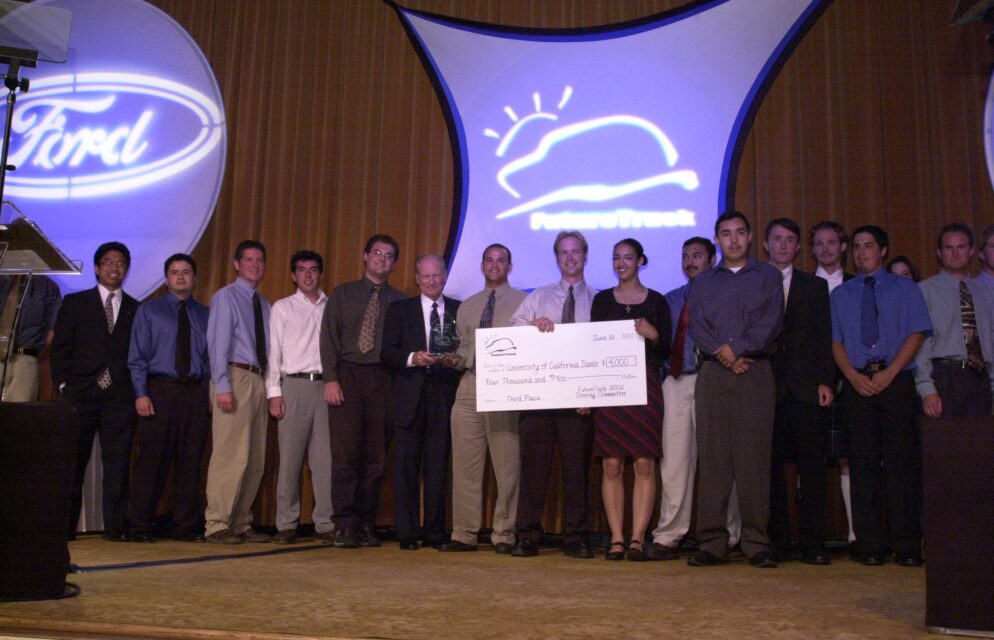

Year Three 2001-2002

- 1st Place – University of Wisconsin – Madison

- 2nd Place – Michigan Technological University

- 3rd Place – University of California, Davis

- 4th Place – Cornell University

- 5th Place – Pennsylvania State University

- 6th Place – West Virginia University

- Best Use of Advanced Technologies – University of California, Davis

- Lowest Regulated Greenhouse Gas – University of Wisconsin – Madison

- Lowest Regulated Emissions – Michigan Technological University

- Best Acceleration – Michigan Technological University

- Best Dynamic Handling – University of Tennessee, Knoxville

- Best Off-Road Performance – West Virginia University

- Best Consumer Acceptability – University of California, Davis

- National Science Foundation Outstanding Faculty Advisor Award – John Beard, Michigan Tech

Year Four 2002-2003

- 1st Place – University of Wisconsin – Madison

- 2nd Place – University of California, Davis

- 3rd Place – Michigan Technological University

- 4th Place – Georgia Institute of Technology

- 5th Place – Pennsylvania State University

- 6th Place – Cornell University

- Best On-Road Fuel Efficiency – University of Wisconsin – Madison

- Lowest Greenhouse Gas Emissions – West Virginia University

- Lowest Regulated Tailpipe Emissions – Georgia Institute of Technology

- Best Acceleration – Georgia Institute of Technology

- Best Off-Road Performance – University of Wisconsin – Madison

- Best Dynamic Handling – University of California, Davis

- Best Oral Design Presentation – Pennsylvania State University

- Best Technical Report – University of Wisconsin – Madison

- Best Consumer Acceptability – Georgia Institute of Technology

- Best Vehicle Design Inspection – University of Wisconsin – Madison

- Best Appearing Vehicle – University of Maryland

- 1st Place, Delphi Advanced Powertrain Technology Award – University of Wisconsin – Madison

- 2nd Place, Delphi Advanced Powertrain Technology Award – University of California, Davis

- 3rd Place, Delphi Advanced Powertrain Technology Award – Pennsylvania State University

- 1st Place, Cisco Systems Telematics Award – University of California, Davis

- 2nd Place, Cisco Systems Telematics Award – University of Idaho

- 3rd Place, Cisco Systems Telematics Award – University of Tennessee, Knoxville

- 1st Place, National Instruments Most Innovative Use of Virtual Instrumentation – University of Tennessee, Knoxville

- 2nd Place, National Instruments Most Innovative Use of Virtual Instrumentation – California Polytechnic State University, San Luis Obispo

- 3rd Place, National Instruments Most Innovative Use of Virtual Instrumentation – Virginia Tech

- 1st Place, The MathWorks Modeling Award (tie) – Cornell University and Georgia Institute of Technology

- Special Recognition, The MathWorks Modeling Award – West Virginia University

- Best Workmanship – University of Wisconsin – Madison

- Best Appearance – University of Maryland

- Dr. Donald Streit Sportsmanship Award – Unknown

- Sprit of the Challenge – Virginia Tech

- Most Improved Team -California Polytechnic State University, San Luis Obispo

- National Science Foundation Outstanding Faculty Advisor Award – Dr. David Holloway, University of Maryland

Year Five 2003-2004

- 1st Place – University of Wisconsin – Madison

- 2nd Place – Pennsylvania State University

- 3rd Place – Georgia Institute of Technology

- 4th Place – Michigan Technological University

- 5th Place – Ohio State University

- 6th Place – University of Idaho

- BP Best On-Road Fuel Efficiency- University of Wisconsin – Madison

- Lowest Greenhouse Gas Emissions – University of Wisconsin – Madison

- ArvinMeritor Lowest Regulated Tailpipe Emissions – Texas Tech University

- Best Acceleration – Georgia Institute of Technology

- Best Dynamic Handling – Ohio State University

- Best Oral Presentation – University of Wisconsin – Madison

- Best Technical Report – University of California, Davis

- Best Consumer Acceptability – University of Wisconsin – Madison

- Best Vehicle Design Inspection – Pennsylvania State University

- Best Appearing Vehicle – University of Tennessee, Knoxville

- Best Workmanship – Pennsylvania State University

- Spirit of the Challenge – West Virginia University

- Dr. Donald Streit Sportsmanship Award – Pennsylvania State University

- Most Improved Team – University of Alberta

- National Science Foundation Outstanding Faculty Advisor Award – Dr. Daniel Haworth, Pennsylvania State University

- 1st Place, Delphi Advanced Powertrain Controls Award – University of California, Davis

- 2nd Place, Delphi Advanced Powertrain Controls Award – Ohio State University

- 3rd Place, Delphi Advanced Powertrain Controls Award – Michigan Technological University

- 1st Place, The MathWorks Modeling Award – Ohio State University

- 2nd Place, The MathWorks Modeling Award – Pennsylvania State University

- 3rd Place, The MathWorks Modeling Award – Michigan Technological University

- 1st Place, National Instruments Most Innovative Use of Virtual Instrumentation – University of Tennessee, Knoxville

- 2nd Place, National Instruments Most Innovative Use of Virtual Instrumentation – Texas Tech University

- 3rd Place, National Instruments Most Innovative Use of Virtual Instrumentation – Ohio State University

- 1st Place, Visteon Innovative Use of Electronics Award – University of Tennessee, Knoxville

- 2nd Place, Visteon Innovative Use of Electronics Award – Pennsylvania State University

- 3rd Place, Visteon Innovative Use of Electronics Award – University of Wisconsin – Madison

Sponsors

Below are the list of sponsors who helped make FutureTruck possible:

FutureTruck Media Coverage

Select a tab above to view content

- 2001 Media Report

- 2003 Media Report

- WVU shares FutureTruck 2000 title in Arizona- June 16, 2000

- SEAS team prepares for FutureTruck competition – February 1, 2001

- UC Davis Students Develop an Environmentally Friendly Sport Utility Vehicle Using Simulink – Summer 2001

- University of Wisconsin students win FutureTruck competition – June 25, 2002

- Computer Controller Makes for Better Hybrid Electric Vehicles – Summer 2002

- Students Re-Engineer Ford Explorer to Burn Less Gas – Summer 2002

- FutureTruck wins national competition – Fall 2002

- Badger victory: Wisconsin students meet FutureTruck challenge – Sept. 4, 2003

- 2003 FutureTruck Competition – Fall 2003

- 2000 University of Maryland FutureTruck Design Description – March 5, 2001

- Control Strategies for a Series-Parallel Hybrid Electric Vehicle – March 5, 2001

- The Development of a Fourth Generation Hybrid Electric Vehicle at West Virginia University – March 5, 2001

- Analysis of Performance Results from FutureTruck 2001 – March 4, 2002

- Design and Optimization of the University of Wisconsin’s Parallel Hybrid-Electric Sport Utility Vehicle – March 4, 2002

- Design and Construction of the University of Tennessee, Knoxville FutureTruck 2000/2001 Parallel Hybrid Vehicle – March 4, 2002

- Degree of Hybridization Modeling of a Hydrogen Fuel Cell PNGV-Class Vehicle – June 3, 2002

- Integration of WAVE and ADVISOR Simulations for Optimization of a Hybrid Electric Sport Utility Vehicle – October 21, 2002

- Design and Development of the Texas Tech Fuel Cell Powered FutureTruck – March 3, 2003

- Cal Poly’s Series Hybrid Electric Vehicle for FutureTruck 2002 – March 3, 2003

- Design and Development of the 2002 Cornell University Hybrid Electric Vehicle – March 3, 2003

- The Excite – The University of Maryland’s Pre – Transmission Parallel Hybrid Ford Explorer – March 3, 2003

- Design and Development of the 2002 Michigan Tech FutureTruck, a Parallel Hybrid Electric Vehicle – March 3, 2003

- Design of a Zero Emission Sport Utility Vehicle for FutureTruck 2002 – March 3, 2003

- Development of the University of Idaho Parallel Hybrid FutureTruck – March 3, 2003

- Design and Development of the Texas Tech Fuel Cell Powered FutureTruck – March 3, 2003

- Design and Development of the 2002 UC Davis FutureTruck – March 3, 2003

- The 2002 Ohio State University FutureTruck – The BuckHybrid002 – March 3, 2003

- Georgia Tech’s FutureTruck Split-Parallel Hybrid SUV Design – March 3, 2003

- Design and Testing of a Prototype Midsize Parallel Hybrid-Electric Sport Utility – October 25, 2004

- Penn State FutureTruck Hybrid Electric Vehicle: Light-Duty Diesel Exhaust Emission Control System to Meet ULEV Emissions Standard – October 24, 2005