Written By: Jake Berg, OSU Communications Manager

The EcoCAR Mobility Challenge tasks 12 university teams to apply advanced propulsion systems, as well as connected and automated vehicle technology to improve the energy efficiency, safety and consumer appeal of the 2019 Chevrolet Blazer – Specifically for the carsharing market.

While re-engineering the gasoline-powered vehicle into a hybrid vehicle, the Ohio State University EcoCAR Team has identified various multiple challenges: How much power should the electric motor and gasoline engine generate? How much energy should be harnessed by regenerative braking? How can the car maximize its energy efficiency?

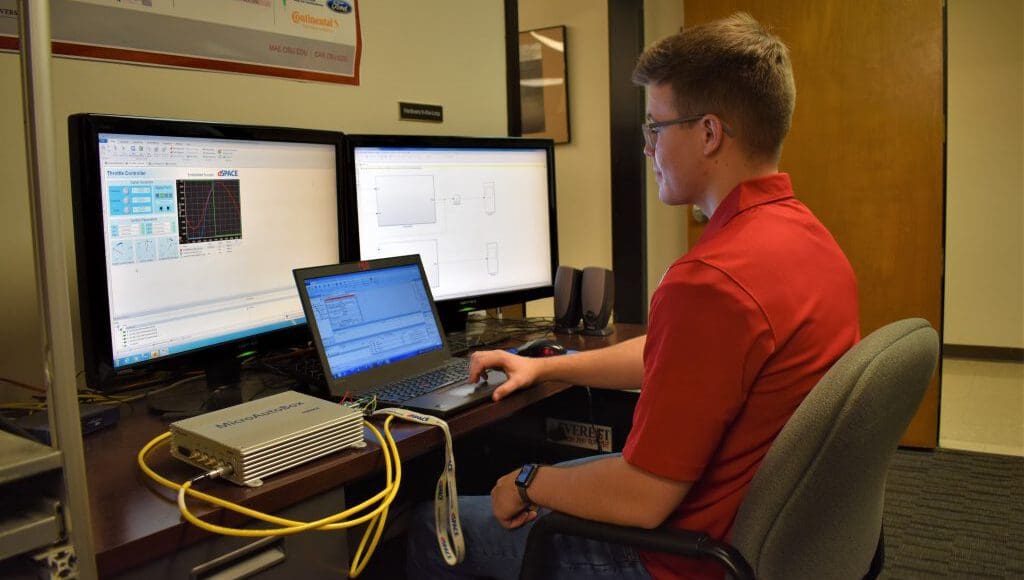

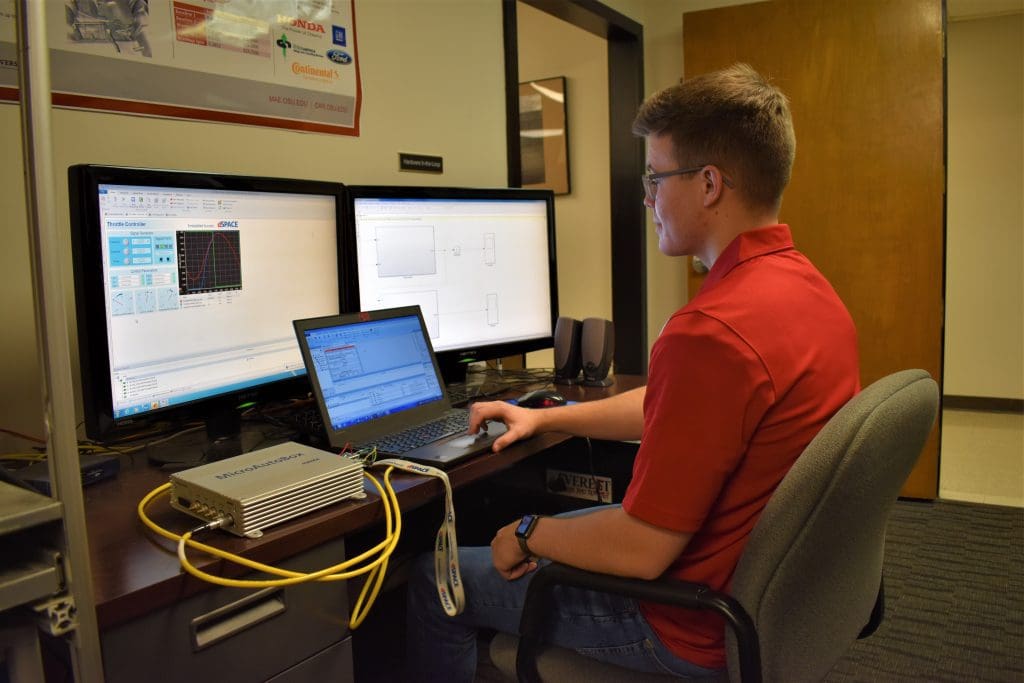

As with most modern vehicles, the Blazer’s response when the driver presses the accelerator or brake pedal is determined by powerful computers called controllers. Each controller must be designed specifically for the new hybrid powertrain to achieve maximum efficiency. Ohio State EcoCAR wants to achieve a 15 percent increase in fuel economy compared to the stock Blazer, so it needs the best hardware and software available.

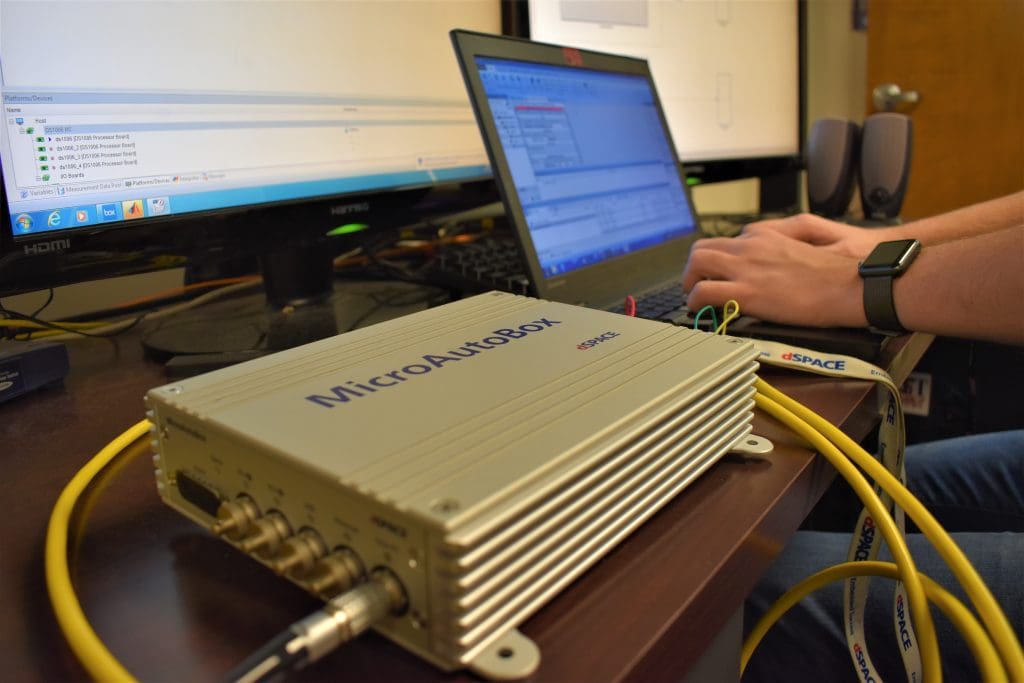

Leadership Competition Sponsor, dSPACE, provided all 12 EcoCAR teams with their own MicroAutoBox II controllers. Instead of reprogramming each controller individually, the MicroAutoBox connects to the Blazer’s stock controllers, and it sends and receives data to keep the vehicle’s new hybrid powertrain operating at maximum efficiency. Most production vehicles do not use this type of controller, but this setup allows teams to easily change the powertrain’s behavior.

Kristina Kuwabara, Ohio State EcoCAR’s controls, systems modeling and simulation team leader, has used dSPACE’s MicroAutoBox and hardware-in-the-loop simulator for nearly three years. She said that dSPACE equipment provides valuable access to detailed controls data in an engineer-friendly format, which will help the team determine exactly how much power the gasoline engine and electric motor should generate at any given moment.

“We are in the research realm, so we need the prototype side of things,” Kuwabara said. “We can change things on the fly, run tests, try different calibrations and see the detailed vehicle component results. The user interface is what really sets dSPACE’s software apart.”

dSPACE’s contributions not only help EcoCAR students engineer a better vehicle, but they also provide them with the skills they need to secure internships and jobs because many automotive manufacturers already use dSPACE equipment.

Vivek Moudgal, Vice President of Sales at dSPACE Inc. and an Ohio State alumnus, said that dSPACE has been involved in AVTCs since EcoCAR: The NeXt Challenge. According to Moudgal, academics have always been important to the company.

“dSPACE has been very supportive of the academic use of our tools far longer than our involvement in AVTCs,” Moudgal said. “Academic use is very important to dSPACE, but it tends to be more theoretical. You study a concept in class, then you go to the lab and implement it through experiments to confirm the theory you have studied. Competitions like EcoCAR go far beyond, and they are surrogates for on-the-job training.”

At the EcoCAR Year One Winter Workshop, teams received hands-on training from dSPACE professionals to ensure they get the most out of the technology.

The MicroAutoBox’s flexibility, capability and reliability make it the perfect controller for the Blazer over the next four years. Ohio State EcoCAR has used dSPACE’s technology for over a decade, and it has never skipped a beat. Thanks to dSPACE, EcoCAR engineers will excel in their studies, internships and careers.