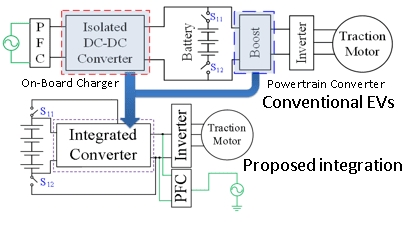

The University of Tennessee’s EcoCAR 3 innovation team is working to design a new power converter that will improve the performance of electric vehicles (EVs). The team is working to merge two existing power converters – the powertrain boost and  isolated DC-DC converter of the on-board charger – into a new integrated converter – that will be cheaper, smaller, and more efficient.

isolated DC-DC converter of the on-board charger – into a new integrated converter – that will be cheaper, smaller, and more efficient.

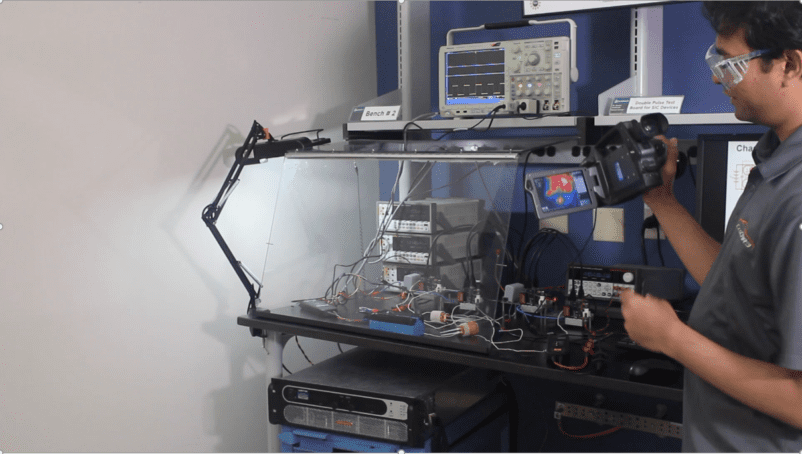

“The powertrain and on-board charger on EVs today have separate packaging. However, when the vehicle is in charging mode, the powertrain converters are idle and when the vehicle is in traction mode, the on-board charger converters are idle,” said Saeed Anwar, PhD student and UT’s Innovation Team Lead. “With the demand of fast charging and longer driving range, the EV chargers require at least 6.6 kW power flow requirement which is known as “level two charging.” By combining power converters of powertrain system and on-board charging system, the amount of power switches, magnetics, capacitors and heat sinks can be reduced.”

Team Tennessee is working to gain advantages from the integrated converter and to address the design challenges for the integration. With the reduction of the number of power switches, magnetics, capacitors, and heat sink, the cost, converter weight, and volume can be reduced significantly. Ultimately, this integrated converter will save volume in EVs, which can be used as cargo space or extra battery space that would provide higher driving range.