This blog post was written by Chris Mottaz, and is a personal story from his point of view. Thanks for sharing your story, Chris!

When I started working on the Purdue EcoCAR 2 Team, I was interested in it purely as a recreational club where I could discuss advancements in the automotive industry. I wanted to talk to people that knew the difference between a PHEV and an HEV, and why an electric vehicle doesn’t count as a hybrid – surprising as it may be, I still get questions about these differences. I wanted to talk about technology – I had some ideas on what I thought a “perfect” hybrid would be, and I needed a group that could challenge my ideas. The challenges that I endured were far beyond my expectations of the EcoCAR competition – and I loved it!

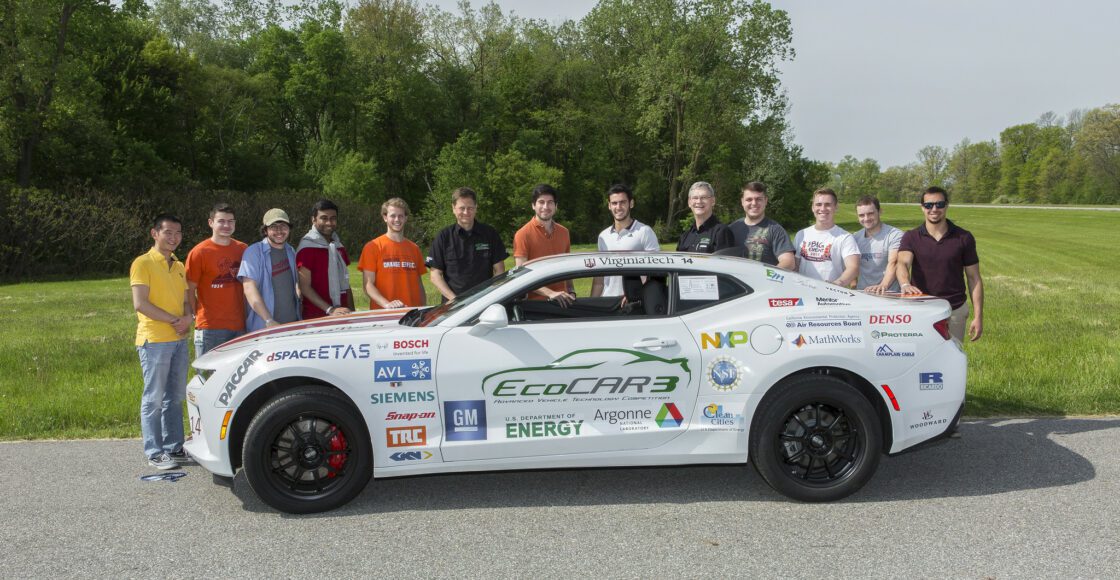

The Purdue EcoCAR Team is comprised of people with deep knowledge of automotive technology. From the professors that lead the program to the sophomores and freshmen, I found a group where everyone would willingly contribute in any way that they could. They were always supportive, thought-provoking, and sometimes difficult (but in a good way). Their variety of experience and knowledge proved a constant challenge for any decision or idea that I had.

Chris Mottaz, former Purdue EcoCAR Team member and current Chrysler Group employeeThe team was the pseudo-salon discussion group that I had hoped for, but also a mini-experiment akin to a start-up. I gained useful experience that could come from starting a new company – but this came without any of the financial or career risk. I developed management skills, technical skills, communication skills, interpersonal skills and confidence.

Recruiters loved seeing EcoCAR on my resume. I can’t count how many times I heard “I see that you have EcoCAR on your resume. Tell me about that.” I told them how I worked on a team that designed a simulator that physically represented a mid-size sedan. I told them how we had learned to use powertrain control software to simulate an entire vehicle, and how we were able to adapt that software to test control strategies. I explained that I helped develop the timeline for competition deliverables, and the business case that I had to develop to obtain a grant for our car simulator. “Wow! This sounds like it was a great opportunity – you clearly learned a lot!” Yes, I did.

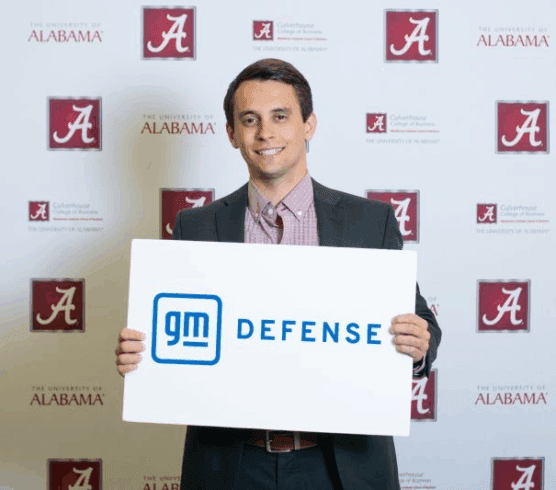

After graduation, I was accepted into a prestigious rotational program at Chrysler Group that accepts only 30 applicants each year. The company would pay for me to get a master’s degree, I would work in 7 different departments within the company over 4-month rotations, and I would get to use one workday every week to study. I had impressed the recruiters (and am now one myself!) and landed my dream job.

But landing a great job is not the only benefit of the EcoCAR competition. The main purpose is to develop the next generation of automotive engineers. I knew step 1 was to get a sweet job (check!), and step 3 was making money from said job (profit!), but my EcoCAR experience was also critical in step 2: building a great work ethic.

My first rotation was working in the Human Machine Interface (HMI) group. The purpose of HMI is to apply scientific methods to all parts of the vehicle that the customer will interact with and to determine the reason why someone likes or dislikes a vehicle. Basically, HMI attempts to apply scientific reasoning to subjective ratings.

I worked on controls and displays: buttons, screens, switches, toggles, etc. Sometimes our process worked (almost all of our vehicles controls receive “excellent” or “very good” ratings from Consumer Reports), and sometimes we needed to start over. For example, in one experiment I couldn’t find any strong correlation between fingerprint area and anthropometric data – back to the drawing board. I had experience with ergonomics and anthropometry from designing the car simulator, but I didn’t have much experience with controls and displays. Luckily, I had my EcoCAR work ethic and capacity to learn to drive me forward.

EcoCAR had given me the tools to overcome any obstacles that I encountered. If I didn’t know much on a topic, I completed a literature review using the same methods I used in EcoCAR 2. If I had a lot of deliverables, I developed a timeline to complete them – same as EcoCAR 2. If I was struggling, I knew how to find the source of my struggles and ask for help – same as EcoCAR 2. Almost everything that I did during my time on the Purdue EcoCAR 2 Team has directly related to my success in the automotive industry. But the most important thing that I learned in the EcoCAR 2 competition? How to deliver.