In 1995, Becky Gunn stared at the television screen in awe as she watched the unveiling of the Insurance Institute for Highway Safety’s (IIHS) first ever round of crash tests. She had always loved cars, sketching models in her free time, but watching those tests was the moment she knew she wanted to be in the business of saving lives through the evaluation of car safety.

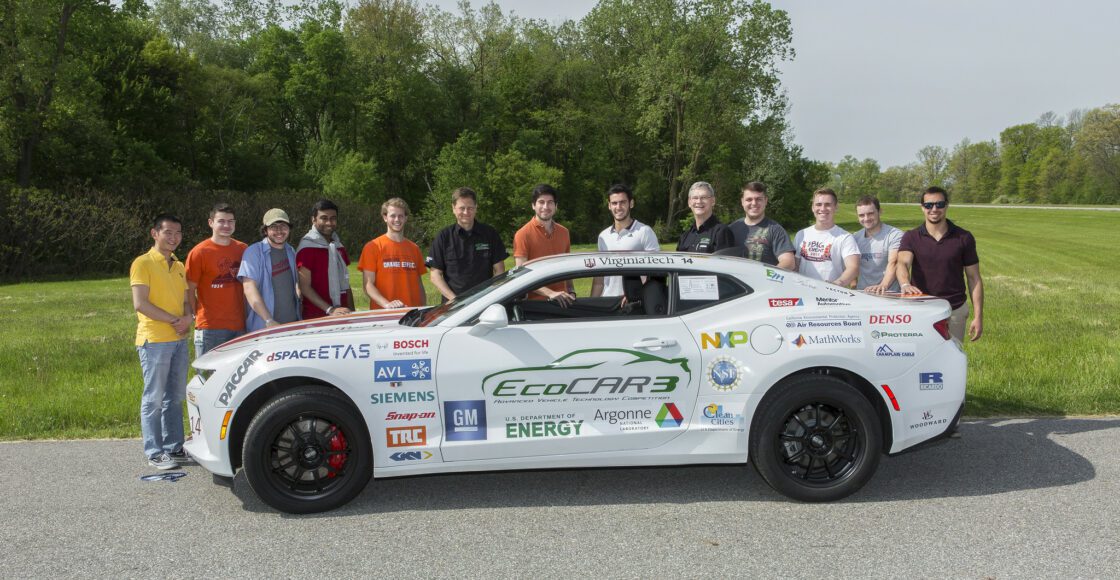

Gunn, who is now an IIHS research engineer, got her first taste of real-world engineering during her experience with the University of Wisconsin Challenge X team and attributes it to where she is in her career today.

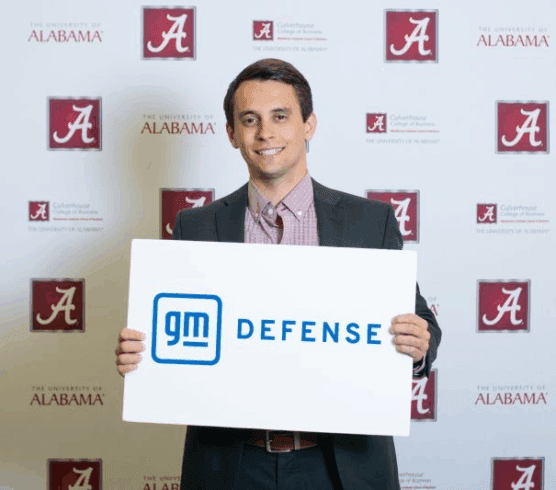

“I believe Challenge X definitely got my foot in the door in the auto industry and without that experience I wouldn’t have been recognized by companies like General Motors and Ford,” Gunn said, “And I certainly wouldn’t have been able to request the department I wanted to work in.”

At a workshop, Gunn spoke with a GM employee and immediately won them over with her excitement and knowledge about cars. She was then hired as an intern and requested to work in vehicle safety. Over the next two summers she gained invaluable experience running simulations of crash tests, assisting on full-scale crash tests and component tests and learning about real-world crash investigation.

After graduation, Gunn went on to work for the National Highway Traffic Safety Administration (NHTSA) as a contractor, working on research projects for new crash tests, dummies and pedestrian crash tests. Research like this lays the foundation for potential new laws or consumers tests.

Today, Gunn’s work at IIHS focuses on pedestrian safety.

“I look at real-world crashes that involve pedestrians and I’m trying to analyze what we can change on cars that will cause less injury to pedestrians when they’re hit,” she said.

Planning for a crash test takes days, with engineers ensuring everything from the car setup to the dummy are in place. After the test, the data is compiled into a report made available to the public on the IIHS website.

Gunn enjoys hands-on experience with cars, and her experience during Challenge X was no exception.

“To know that you went from a car that was completely torn apart, and didn’t look like it would ever function, then to be able to actually drive it around and know that you designed components that make it function, was very rewarding,” Gunn said.

Gunn says participating in Challenge X enhanced her classroom education.

“At times I believe that I got a lot more out of Challenge X than I did in most of my classes. You learn so many hands-on, real-world applications that it not just supplements book learning, but I think it’s an essential part of becoming a good engineer,” she said.