Mike Ogburn first became involved in energy efficiency research and implementation during the early days of Advanced Vehicle Technology Competitions (AVTC) with FutureCar in 1998. After graduating from Virginia Tech, he worked at Ford Motor Company as a product development engineer, developing the first fuel cell powertrains with Ballard Fuel Cells for the Hydrogen Fuel Cell Focus, and as a calibration engineer tuning software systems on the Hybrid Escape. But after three years at Ford, Ogburn wanted a change from working on vehicles for a time.

However, he did not plan for how far this break would take him or how much time he would take to come to a decision about his next step in life. For over two years following his decision to take a break from Ford, he lived aboard a boat with his now wife, Tina. Together, they set out on an old 37 foot sailboat, leaving Florida for the Bahamas for 6 months. They eventually upgraded the boat with solar powered refrigeration and sailed 9,000 miles to 32 countries around the Caribbean, including Venezuela, Columbia, and several Central American countries before arriving back in Florida in 2006. By the end of his trip, Mike says he’d had plenty of time to think.

“I was tired of working on just cars,” Ogburn remembers. “Even electric cars get stuck in traffic. I wanted to work on more types of renewable energy, to work more on energy efficiency to make a bigger difference in the world.”

Ogburn continued his career at Rocky Mountain Institute, an independent, nonprofit think-and-do tank with the mission to drive the efficient and restorative use of resources. While there, he worked with heavy truck fuel efficiency and lightweight vehicles. Ironically, a lightweight vehicle from University of Wisconsin had beaten his FutureCar team in 1999.

“At RMI, I realized there’s much more to saving the planet than just better powertrains in cars, or better furnaces in houses. True energy efficiency needs a broader perspective if is going to succeed at the lowest possible cost.”

Experience at the Rocky Mountain Institute led Ogburn to serve on the board for North American Council for Freight Efficiency (NACFE), an organization that seeks to ensure the safe, efficient and profitable future of the trucking industry. He also served on an advisory board organized by the International Council on Clean Transportation (ICCT) that advised the EPA on heavy truck fuel efficiency rules announced by the White House in August 2011.

Today he works for Clean Energy Economy for the Region (CLEER), an organization that develops and implements energy efficient programs for Garfield Clean Energy and its individual partners, striving to achieve energy savings.

One of Ogburn’s recent successes was through his work at new Recreation Center built in 2007 in Carbondale, CO. While the building was already a LEED-Platinum facility with a 70,000 watt solar electricity system, his work helped cut the building’s energy use by an astonishing 40 percent with no additional capital investment. The operational improvement to software controls paid for itself in a month, and has saved roughly $10,000 in just the first 12 months he says. “These building cost savings results link directly back to my involvement in AVTC, where I learned how to build energy systems on vehicles before refining that knowledge working for Ford on advanced vehicles,” Ogburn said.

CLEER has a vehicle efficiency program that works with fleet efficiency solutions to help reduce petroleum consumption. His work has coordinated large regional fleet-efficiency workshops and even helped deploy a demonstration project of Neighborhood Electric Vehicles. Additionally, Ogburn is one of two people to run the Western Slope Compressed Natural Gas (CNG) Collaborative, a partnership between local governments, the oil and gas industry, and businesses in the region to help ensure that refueling infrastructure, repair shops, dealer support and other services are in place to support CNG vehicles of all types. The goal is to keep money within the community rather than importing oil, Ogburn says.

Having grown up in a passive solar house in Virginia, energy efficiency was always important to Mike and working with FutureCar ‘98 led him to continue his dedication by going on to participate in FutureCar ’99 and FutureTruck ‘00. In doing so, his graduate school was paid for by National Renewable Energy Laboratory (NREL), which wanted his team’s data for their ADVISOR (Advanced VehIcle SimulatOR) program. ADVISOR enables a user to simulate a conventional, hybrid, electric, or fuel cell vehicle over a city or highway drive cycle to predict vehicle performance. He and his team helped release some of the first fuel cell data ever made public and authored several SAE papers on their findings that won awards when presented at the 2000 SAE Congress in Detroit.

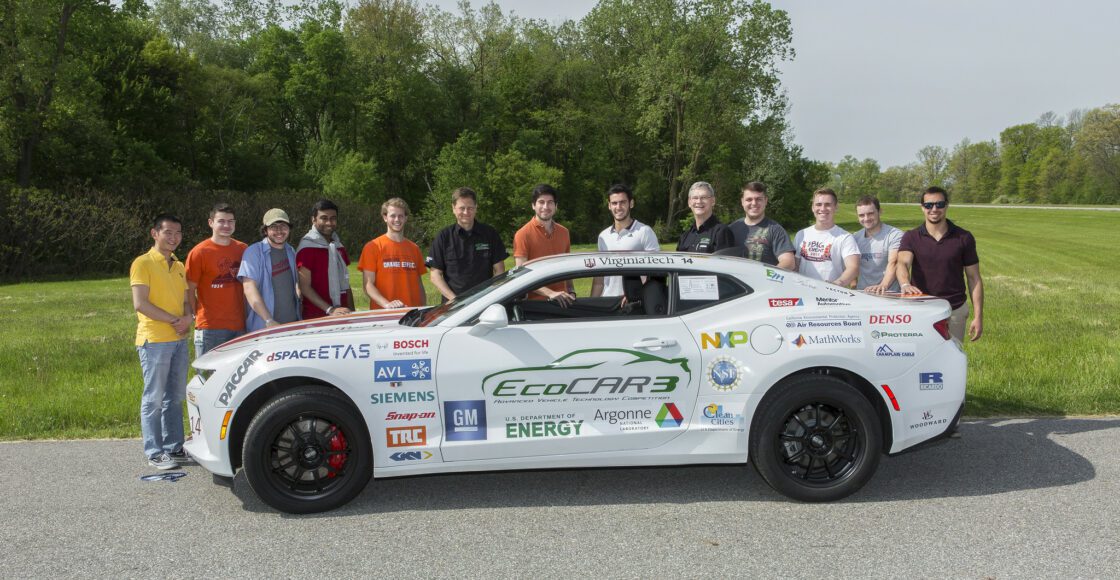

For three years, Ogburn served as team leader for Virginia Tech’s Hybrid Electric Vehicle Team, working on all aspects of the competition, from organizing teams and overseeing projects to presenting and dynamic testing at competitions. While a lot of his focus was on management, he also spent long hours in the shop, using his skills to help with other projects, such as welding. His most notable experience was the opportunity to share the podium with then Secretary of Energy Bill Richardson.

Since his early experiences, Ogburn doesn’t simply talk the talk. Living sustainably and efficiently has become a part of his everyday life. He tries to ride his bike to work once a week. He owns a Prius hybrid and a small, efficient SUV that lets him and his family reach mountain trailheads on weekends. His office is in a solar-powered, renovated, recycled school building and only uses lights in the winter – the rest of the year they rely solely on skylights.

Ten solar panels on his home’s roof cover about 60 percent of his home’s electricity needs. When he installed the system, he had to do some wiring and decided to run extra wires to his garage to support an electric vehicle plug in the hopes of someday owning an electric vehicle.

“Twelve years after working on FutureCar, I can finally buy a plug-in vehicle made in the USA,” Ogburn says. Even better, he says, is knowing that his team members from VT are working on electric vehicles at three different US car companies. “AVTC really made a difference in our lives, and in the energy future of this nation.”